自動ポップコーン生産ラインは、さまざまな種類のポップコーンを現代的に生産するための設備で、時間と労力を節約します。工業用ポップコーン製造機の膨張技術は、温度と熱風循環の効果的な組み合わせであり、高い熱効率、低コスト、高度な自動化、簡単な操作、環境保護、騒音なしを実現しています。

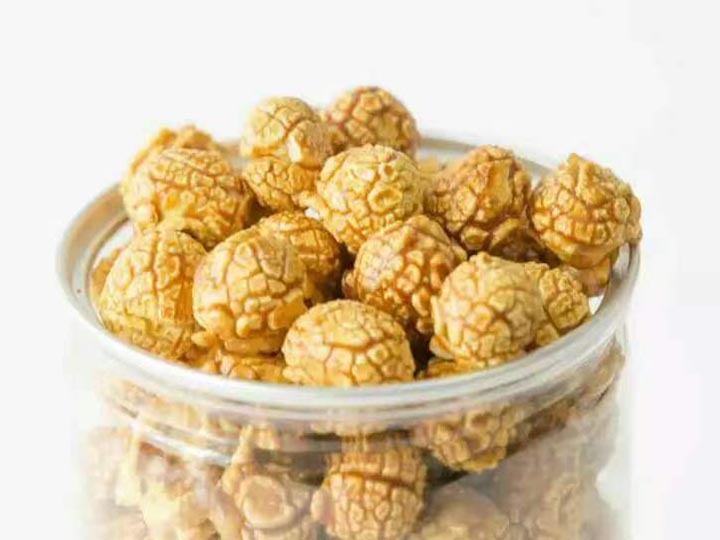

自動ポップコーン処理ラインのポップコーンの品質は安定しており、球状形成率が高く、砂糖が均一にコーティングされており、レシピの調整も容易です。完成品の味は、オリジナルフレーバー、キャラメルフレーバー、フルーツフレーバー(イチゴ味など)、ココナッツフレーバー、チョコレートフレーバーなどに調整可能です。

このポップコーン生産ラインは、1日に2–4トン(12時間ベース)を生産でき、小規模および中規模の事業に最適です。より大きいまたは小さい容量のラインが必要な場合、Taizyは機械をカスタマイズできます。お気軽に生産計画についてお問い合わせください。

自動ポップコーン生産ラインの概要

自動ポップコーン生産ラインは、モジュール設計を採用しており、顧客の工場に合わせて調整可能で、さまざまな方法で生産できます。

このポップコーン製造機は電磁加熱を採用しており、省エネで環境に優しく、自動温度制御、自動攪拌、自動排出を実現しています。

この商業用ポップコーン生産ラインの特徴は、プロセスをより便利で効率的にし、労働者の労働負担を大幅に軽減することです。さまざまなタイプのポップコーンを作ることができ、キャラメルポップコーン、チョコレートポップコーン、フルーツポップコーンが人気商品です。ポップコーンの形状もボール、マッシュルーム、スノーフレークなどを選べます。

自動ポップコーン生産ラインの用途

- 食品加工工場: プレーン、スイート、キャラメル、フレーバー付きポップコーンの大規模生産に使用されます。

- スナック食品工場: スーパーマーケットやオンライン販売向けのバッグおよび缶詰のポップコーンの連続生産に適しています。

- 映画館やテーマパークへの供給: 映画館や遊園地に一貫した品質のポップコーンを供給するための集中生産。

- ベーキングおよび菓子工場: ケーキやデザート、チョコレート製品の材料や装飾として使用されます。

- 中央厨房および食品流通センター: 標準化された商業用ポップコーン生産と一元的な流通向け。

- 輸出志向の食品メーカー: 国際的な食品安全基準を満たすパッケージ入りポップコーンの大量生産向け。

自動ポップコーン生産ラインの作動動画

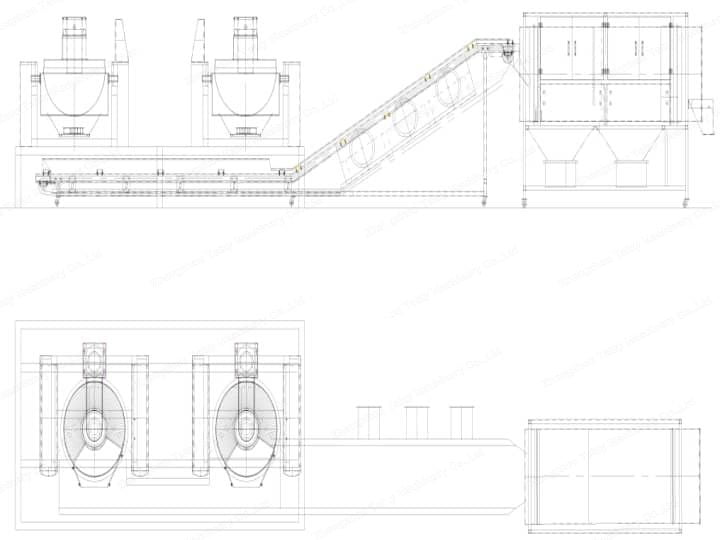

自動ポップコーン加工ラインの主要機械

処理:

ポップコーン製造機 – 冷却コンベア – 回転ドラムふるい機

機械リスト:

| 注文 | アイテム | 量 |

| 1 | ポップコーン製造機 | 2 |

| 2 | 冷却コンベア機 | 1 |

| 3 | ロータリードラムふるい機 | 1 |

ポップコーン製造機

ポップコーン製造機は、自動ポップコーン生産ラインでコーン原料をポップさせるために使用されます。工業用ポップコーン機は、自動温度制御、自動混合、自動排出の機能を備えています。電磁加熱を使用してエネルギー節約が可能です。1時間あたり240kg-300kgのポップコーンをポップさせることができます。

| 機械型式 | TZ-CZ90XJB-DC |

| 機械サイズ | 1380*1610*1590mm |

| 有効加工寸法 | φ900mm |

| 総重量 | 600kg |

| 力 | 43kw |

| 電源 | 380V 50HZ |

冷却コンベア機

冷却コンベアベルトは、調理鍋からポップコーンを冷却し、回転ドラムのふるい機に運びます。軸流ファンは、特別な風箱構造を使用しており、ポップコーンを迅速に所定の温度に冷却します。コンベアメッシュベルトは、穴が均一に配置されたステンレス鋼板タイプで、ベルトの速度は調整可能です。

| 機械型式 | TZ-WS60/700 |

| 機械サイズ | 7200×1050×1610mm |

| 有効加工寸法 | 6900×550mm |

| 力 | 1.2KW |

| 電源 | 380V 50HZ |

ロータリードラムふるい機

回転ドラムは材料を螺旋状に運びます。未調理のトウモロコシ、トウモロコシのふすま、その他の小さな残留物をふるいにかけて取り除くことができます。ベルト伝動を使用し、動作中の回転や滑りを防ぎます。

| 機械型式 | WS90/260 |

| 機械サイズ | 2900×1100×1870mm |

| 有効加工寸法 | φ900×2700mm |

| 力 | 0.55KW |

ポップコーン生産ラインの3D設計図

販売のための工業用ポップコーンメーカー機械の特徴

1. 爆米花形状美观均匀。原料爆开膨胀,形成一个大圆球状。

2. 玉米爆率高。爆率接近100%。大大提高了原料的利用率,降低了材料成本,降低了成本,增加了利润。

3. 智能控制 操作简便。通过设置合适的参数,全自动爆米花生产线可以加工不同品种的原料。生产过程无需人工控制。设置搅拌速度后,爆米花生产线将保持恒定速度,确保产品质量一致。

4.自动化程度高。全自动爆米花加工线的产量是单机操作的几倍,温控定时设备统一,进出料一次完成

5.电磁热转换率高,节能。智能加热系统可避免不必要的热量浪费,降低成本,扩大利润空间。

4. 広範囲 にわたり、さまざまな原料に適しています 。原料コストを削減し、利益を向上させることができます。

工業用ポップコーンマシンの価格

自動ポップコーン生産ラインには多くのモデルとタイプがあり、製品の種類によって価格も異なります。機械のコストと工程も価格に影響を与える重要な要素です。コストには、加工のための労働投入、原材料の投入、技術の投入、輸送コストの投入など一連の入力の合計が含まれます。お客様のニーズに応じて適切な機械を推奨します。特別なニーズがある場合は、カスタマイズサービスも提供可能です。

Taizy Machineryは、10年以上の工業経験を持つ食品加工機械のリーディングメーカーです。当社は、ポップコーン製造機と付属機器の完全なシリーズを提供しています。同時に、各顧客に対して包括的で思いやりのあるサービスも提供しています。お気軽にお問い合わせください。

出荷ケース

カメルーンの顧客は最初にキャラメルポップコーン処理プロジェクト用のポップコーンマシンを1台注文しました。モデルと構成を確認した後、迅速に生産を手配し、厳格な工場検査を実施しました。マシンは木箱に梱包され、安全な輸送を確保し、現在カメルーンに無事に出荷されています。顧客はマシンの品質と納期に満足しており、今後容量拡大のために全自動ポップコーン生産ラインの購入を計画しています。Taizyは単一機械と完全な生産ラインの両方のサービスを提供します。