美味しくてユニークな味のため、パフスナック食品はますます人気があり、幅広い市場を持っています。当社は、パフ食品の生産に対する市場の需要を満たすために、一連のプロフェッショナルなコーン押出機とパフスナック生産ラインを開発しました。コーンパフスナック押出機は、原料準備、押出パフ化、フライ、味付け、包装から一回の作業で完了でき、高い自動化度を備えています。パフ食品は、サクサクした食感、消化しやすく、ユニークな香り、持ち運びが簡単で、消費者に理想的なスナック食品です。当社のコーンパフ押出機は多くの国に輸出されています。最近の例は、250kg/hのコーン押出機ドイツへの納品です。機器一式がその国への出荷のために手配されました。

コーンパフ押出機の紹介

コーンパフ製造機は、供給システム、押出システム、回転切断システム、加熱システム、伝達システム、および制御システムで構成されています。高度なスクリュー押出・膨化技術を駆使したパフコーン機は、高温・高圧で材料を熟成・膨化させ、一度に完成させます。ホストは可変周波数速度調整を採用し、生産プロセスの安定性を確保します。

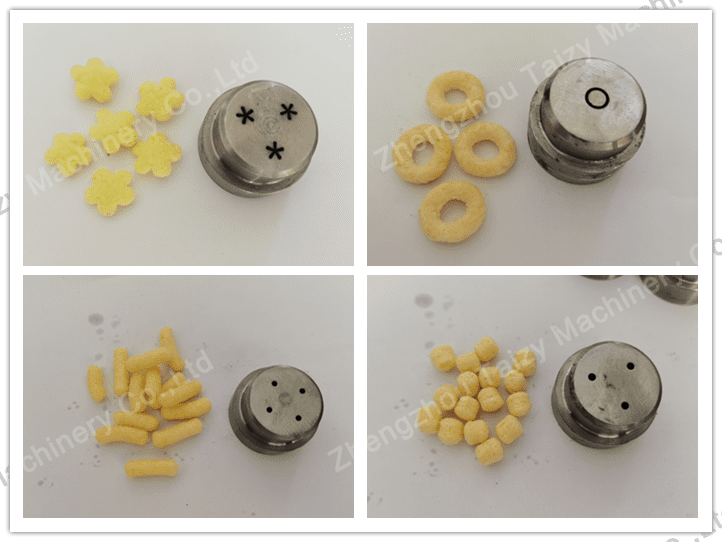

膨化スナック製造ラインは、さまざまなモデル、柔軟な構成、幅広い用途、多様な製品、簡単な操作の特徴を備えています。コーンパフ押出機は、米、トウモロコシ、小麦、その他の穀物、ジャガイモなどの多様な原料に適しています。製品の色や形は多様で、外観は美しく、質感は繊細です。 。

二軸押出機を選ぶ理由?

二軸押出機のバレルには 2 本のスクリューがあり、同時に動作し、安定かつ効率的に相互に噛み合います。一軸押出機は二軸押出機よりも安定性が劣ります。しかし、単軸押出機の押出間隔を狭くすることで、二軸押出機よりも大きな押出力が得られ、より多くの食品の生産に適応します。

二軸コーン押出機 ドイツの押出機は掃除が簡単です。機械使用後は、供給口に廃材を流し込み、スクリュー内に残った廃材を押し出すことでスクリュー内に残留物が残らないようにします。

二軸トウモロコシ押出機は、手頃な価格、高い安定性、大生産量、簡単な洗浄という利点があります。ただし、高い押出力を必要とする一部の食品には適しません。シングルスクリューに比べ、高い押出力を必要とする一部の食品に適しています。

トウモロコシ押出機のご紹介 ドイツ

この顧客は、ドイツのビスケット製品メーカーのエンジニアです。彼は製品開発を担当しています。同社は現在、商品カテゴリーを増やし、膨らんだスナックを作りたいと考えているためです。お客様は、トウモロコシを原料として特定の形状のコーンパフスナックを製造することを検討しました。交渉中、当社の営業マネージャーはお客様の要望に基づいて適合するモデルを提案し、機械の詳細、パラメータ、見積書、テストビデオ、納入写真などを提供しました。当社の専門的なアドバイス、時間内の対応、思いやりのあるサービスにより、交渉は成功しました。スムーズに。このドイツ人の顧客は後で注文しました。

以下は、モデル: TZ-70-II コーンパフ押出機の仕様と、生産ラインで同時に注文された他の機械の機械リストです。

| 入力電圧 | 380V/50HZ |

| 設置容量 | 46KW |

| 消費電力 | 30KW |

| 出力 | 200-250kg/h |

| サイズ | 3.6×1.0×2m |

| ネジの長さ | 1520mm |

| ネジ径 | 70mm |

| メインモーター出力 | 30kw |

| 火力 | 2kw*6 12 |

| 給電電力 | 0.75 |

| 切断力 | 0.75 |

| オイルポンプパワー | 0.37 |

パフスナック加工ラインのその他の主要機械

| 注文 | マシン名 | 技術データ |

| 1 | ミキサー | 収量: 50kg/バッチ 電力: 4kw サイズ:1.0×0.8×1.3m |

| 2 | スクリューコンベア | パイプ長さ:141mm パワー (KW): 0.75 寸法(m):3.0×0.6×2.5 |

| 3 | ベーキングマシン | 寸法(m):5.0×1.3×1.8 出力: 300kg/時間 駆動モーター:0.55kw 電気加熱出力: 45kw |

| 4 | 調味料入れ機 | 電力: 0.55kw+0.37kw ドラム直径:650mm ローラー長さ:1900mm サイズ:5.0×0.8×1.9 |

上記の機械に加えて、いくつかのサポート機器と追加のスペアパーツも注文されました。

コーンパフ製造機の幅広い用途

ドイツのトウモロコシ押出機は、機器の強制押出、パフィング、成形乾燥、油注入、調味料、および対応する補助プロセス。コーンパフ製造機は、パフ食品、サンドイッチ食品、栄養食品、パフスナック食品、ペットフード、水生飼料、およびさまざまな風味のその他の製品に加工されます。

膨化食品機械に関するご質問がございましたら、直接お問い合わせください。