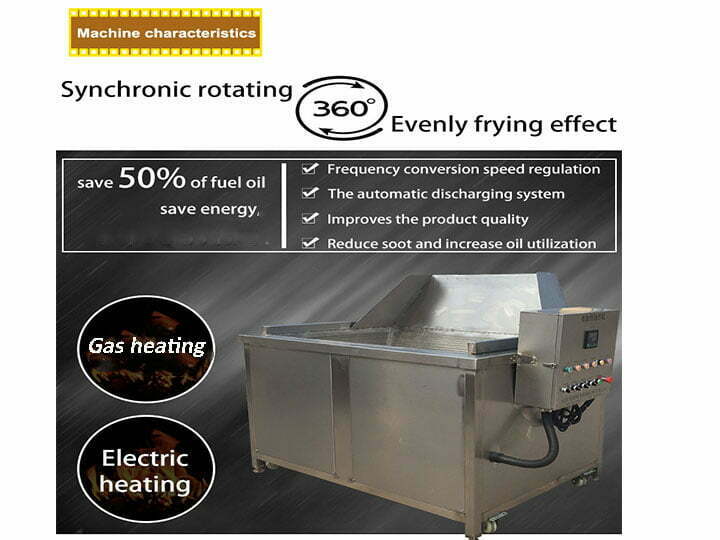

친친 튀김기는 자동 스티어 프라이어 기계로, 친친, 쿨리쿨리 및 기타 종류의 파스타, 견과류 또는 고기를 튀기는 데 적합합니다. 매우 자동화되어 있으며, 친친 생산 라인에서 자주 사용됩니다. 친친 튀김기기는 전기 또는 가스로 가열되며, 조작이 간단하고 안전합니다. 친친 스낵 튀김기는 시장에서 인기가 있으며, 레스토랑, 패스트푸드 매장, 가공 제품 상점, 식품 가공 공장, 구내식당, 호텔 등에서 널리 사용됩니다.

친친프라이어 기계의 장점

| 고품질 스테인레스 스틸 소재 |

| 연속운전 |

| 고효율 |

| 에너지 절약 |

| 석유 절약 |

| 가스/전기 난방 |

| 쉬운 조작 |

| 폭넓은 적용 |

| 합리적인 가격 |

(1) 기계는 식품 안전 및 위생 표준의 요구 사항을 준수하는 식품 등급 304 스테인레스 스틸로 만들어졌습니다. 자동 오일 필터링으로 오일을 깨끗하게 유지하고 제품 품질을 향상시킬 수 있습니다.

(2) 오일의 수명이 길어지므로 오일을 자주 교환할 필요가 없습니다.

(3) 고급 난방 시스템은 에너지 낭비를 더 많이 방지합니다.

(4) 고급 기계 구성 및 제어는 항상 양호한 작동 상태를 유지할 수 있어 출력이 향상됩니다.

(5) 기계의 지속적인 작동으로 작업 효율성이 향상되고 단위 비용이 효과적으로 절감됩니다.

나이지리아 턱받이 튀김기 가동

1. 작동 인터페이스에서 필요한 온도와 작업 시간을 설정합니다.

참고: 기계 부품의 충돌을 방지하기 위해 공급 및 배출을 동시에 시작할 수 없습니다.

2. 가열 시스템을 시작하면 가열 튜브가 가열되기 시작합니다. 설정된 온도에 도달하면 가열이 자동으로 중지됩니다. 동시에 교반 시스템을 시작합니다.

3. 호퍼에서는 원료를 미리 준비해야 합니다. 설정온도에 도달하면 공급버튼을 눌러주세요(동시에 교반도 시작됩니다).

4. 설정된 시간에 도달하면 장치가 자동으로 알람을 울립니다.

5. 방전 버튼을 시작합니다. 오일을 배출하기 위한 배출과정은 10~20초 정도 진행됩니다.