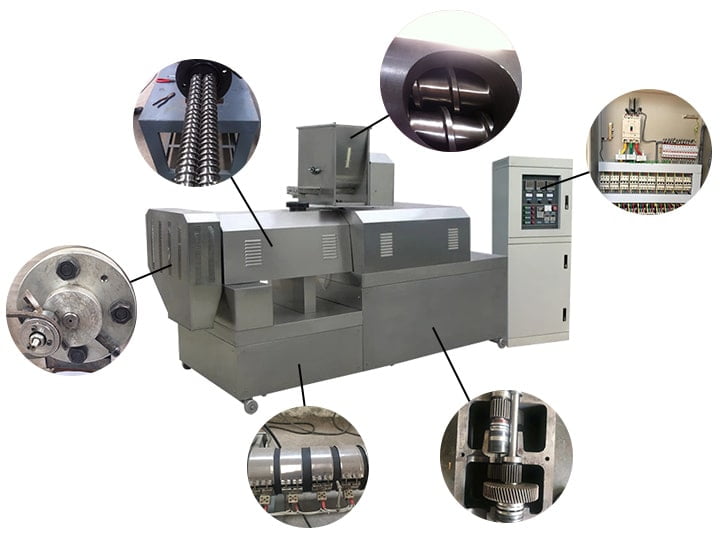

スナック膨張機はスクリュー押出機とも呼ばれています。これは、食品を膨張させるために特化した機械です。スクリュー押出機は、幅広い用途があります。膨張した食品は美味しく、パリッとしていて、持ち運びが簡単で、機械は電子スクリーンで操作が簡単です。したがって、多くの食品加工工場に歓迎されています。

スナックパフマシンの応用

スナック膨張機は、さまざまな形状やフレーバーのスナックを膨張させるために広く使用されています。主に、加工生活において、米、トウモロコシ、大豆、小麦などのさまざまな粉末原材料を膨張させます。このスクリュー押出機は、ポップコーンを膨張させる、膨張スナック生産ラインに適用できます。

この機械は、コーンフレーク、ポテトチップス、サンドイッチせんべい、押し出し揚げスナック、マカロニ、らせん状または貝殻状、その他のさまざまな形状のペットフードの製造に使用できます。膨化機で製造される膨化食品は熟成度が高く、完成品の品質が良好です。

コーンパフ押出機のビデオ

スクリュー押出機パフィングマシンの動作原理

エクストルーダーパフィングマシンの主な動作原理は、機械エネルギーを熱エネルギーに変換することです。機械が回転するときに発生する熱を利用して食品を絞り、熟成させます。膨張した食品の最大の特徴は体積が大きくなることです。二軸押出機は一般に、供給、押出、加熱、回転切断、その他の部分で構成されています。

まず、原料をフィーダー入口に運ぶフィーダーがあります。その後、原料を一定の速度で膨化機本体に押し出します。スクリュー押出機は材料を押し出し、高温高圧下で材料を高温加熱シリンダーに押し込みます。加熱して成形し、金型口から押し出します。出口を通過するときに回転ナイフがあり、膨化した食品を高速で均一に細かく切ります。

スナック製造機の主な機能

膨化機が食品を膨らませると、食品に何らかの影響が生じます。凝集、脱気、脱水、膨潤の機能が含まれます。これらにより、膨化食品は色が鮮やかで、食感が細かく、風味が豊かになります。

凝集力 — 膨化プロセス中に、食品または原材料がしっかりと結合して、小さな個別の断片が形成されることがあります。

脱気 - 食品や原材料に気泡が含まれている場合、膨化プロセス中に気泡が除去されます。

脱水——4%~7%は膨化工程中に原料の水分が失われます。

膨潤 —— 膨張中に沈みやすさや浮きやすさなど、材料のかさ密度が変化します。

スクリュー押出機の利点

- スクリュー押出機はマルチセクションタイプを採用しており、各パーツは独立して温度を制御できます。

- 蒸気と電気の加熱方法を選択でき、顧客の局所加熱要件に応じて便利な加熱方法を選択できます。

- お客様のご要望に応じて押出金型をカスタマイズいたします。

- 独立した電気制御キャビネットを採用して生産パラメータを正確に制御し、操作が簡単、安全、効率的です。

- この機械には多くのモデルがあり、顧客が生産ニーズに応じて適切な出力機械を選択するのに便利です。100-150kg/h、200-300kg/h、300-600kg/hなど。

パラメータ

| モデル | DL65-Ⅲ | DL65-Ⅱ | DL70-Ⅱ | DL80-Ⅱ |

| 入力電圧 | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| 設置容量 | 35KW | 46KW | 46KW | 90KW |

| 消費電力 | 22KW | 30KW | 30KW | 55KW |

| 出力 | 100-150kg/h | 150-200kg/h | 200-260kg/h | 300-500kg/h |

| サイズ | 2.5×0.8×1.8m | 3.2×1.0×1.7m | 3.6×1.0×2m | 4.5×1.2×2.3m |

| ネジの長さ | 1050mm | 1520mm | 1520mm | 1563mm |

| ネジ径 | 65mm | 65mm | 70mm | 80mm |

| モーター出力 | 22kw | 30kw | 30kw | 55kw |

| 火力 | 10kw | 10KW | 12kw | 18kw |

| 給電電力 | 0.75KW | 0.75kw | 0.75 | 1.5kw |

| 切断力 | 0.75KW | 0.75kw | 0.75 | 1.5kw |

| オイルポンプパワー | 0.37Kw | 0.37kw | 0.37 | 0.37kw |

輸出事例