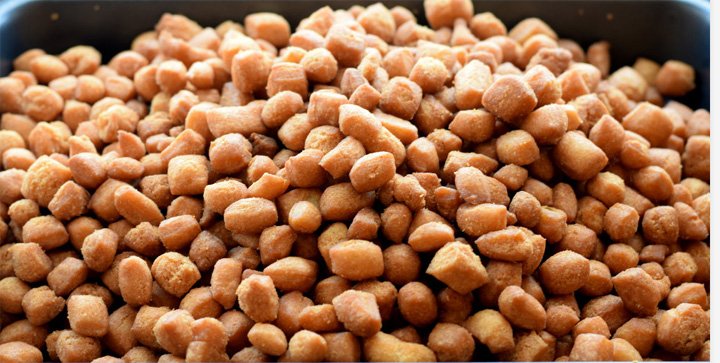

Chinchin is one of the very popular snacks in West Africa. It can be hard, soft, and taste can be sweet or salty. Its style and taste are changeable, and it is a popular snack for afternoon tea, movie night, and game time. Many large food factories and snack food factories in Nigeria, Ghana, and other places have invested money in the production of chin chin food. So how to make chin chin snacks commercially? How to use an industrial chin chin cutter to cut chinchin dough? What are the precautions during the production process?

Máy móc cần thiết để làm đồ ăn nhẹ chinchin

Các bước làm cằm cằm hoàn chỉnh gồm: chuẩn bị nguyên liệu - làm bột - cắt cằm - chiên chinchin - đóng gói.

Đối với các nhà máy sản xuất thực phẩm lớn và nhỏ thì có quy mô khác nhau. Vì vậy thông số kỹ thuật và công suất đầu ra của các loại máy được sử dụng cũng khác nhau.

Các nhà máy sản xuất thực phẩm quy mô lớn có thể sản xuất đồ ăn nhẹ chinchin với số lượng lớn. Vì vậy, nó cần một dây chuyền sản xuất tự động hơn để sản xuất nó. Đối với các nhà máy thực phẩm nhỏ, vốn và không gian có hạn. Vì vậy, có thể chỉ cần một chiếc máy cắt cằm công nghiệp và một chiếc nồi chiên nhỏ là có thể giải quyết được vấn đề.

Làm thế nào để làm chinchin bằng máy làm cằm cằm thương mại?

- Chuẩn bị nguyên liệu

Khi làm cằm cằm thường cần sữa, bột mì, đường, trứng, muối, bột nở và các nguyên liệu khác. Trong quá trình sản xuất thực tế, bạn cũng có thể thêm hạt tiêu, quế và các nguyên liệu khác theo khẩu vị địa phương - Làm bột cằm

Trộn đều các nguyên liệu đã chuẩn bị và tạo thành hình dạng bột. Ở bước này, bạn có thể sử dụng máy trộn bột chuyên nghiệp hoặc nhào bột liên tục bằng tay. - Cắt cằm cằm

Trước khi cắt bột, bạn có thể dùng máy ép bột để ép nhiều lần. Đối với máy cắt cằm công nghiệp, chúng tôi cung cấp máy với nhiều mẫu mã và sản lượng khác nhau cho các khách hàng khác nhau. Nó có một cái nhỏ máy làm cằm cằm phù hợp cho khách hàng lẻ và máy cắt cằm tự động phù hợp cho các nhà máy thực phẩm lớn.

- chiên chín

Mặc dù có phiên bản chinchin nướng nhưng phiên bản chiên là phổ biến nhất. Đối với máy chiên, chúng tôi cũng cung cấp các loại máy có công suất đầu ra khác nhau. Nó có thể thích ứng với nhu cầu của nhiều khách hàng khác nhau. Nồi chiên chinchin có nhiều phương pháp làm nóng khác nhau như dùng điện, dùng gas. Ngoài ra, nó còn có chức năng tự động kiểm soát nhiệt độ. - Bao bì Chinchin

Để đảm bảo bảo quản lâu dài và mang theo thuận tiện, bạn có thể sử dụng máy đóng gói chinchin để đóng gói sau khi nguội. Nó có thể kiểm soát trọng lượng và gam của bao bì.

Những biện pháp phòng ngừa trong quá trình sản xuất

Đối với hương vị chinchin, bạn có thể thêm các nguyên liệu tương ứng để có được hương vị tương ứng. Nên bổ sung thêm khi làm bột chinchin tùy theo nhu cầu của bạn hoặc nhu cầu của khách hàng địa phương.

Nó có các phiên bản cứng, mềm và ở giữa. Nếu muốn bánh chinchin mềm, bạn nên cho thêm bơ và bột mì lên men vào bột khi làm bột. Nếu bạn muốn chinchin cứng, không thêm trứng và bột nở mà có thể thêm sữa.

Khi cắt bột, bạn có thể thay thế máy cắt cằm công nghiệp để tạo thành nhiều hình dạng, kích cỡ khác nhau. Chúng tôi có thể tùy chỉnh theo nhu cầu của khách hàng.

Chiên là bước quan trọng nhất trong việc xác định hình dáng của cằm. Trước khi chiên, đầu tiên bạn nên cho vài miếng bột vào để kiểm tra. Nếu bột đọng lâu ở đáy, bạn cần tăng nhiệt độ lên rồi mới chiên. Nếu bột nhanh chóng nổi lên trên bề mặt. Bạn cần giảm nhiệt độ chiên. Đợi đến khi bột có trạng thái nở dần là nhiệt độ dầu vừa phải.

Nếu muốn đảm bảo cằm có thể giữ được độ giòn lâu hơn, bạn nên bảo quản hoặc đóng gói sau khi đã nguội hoàn toàn.