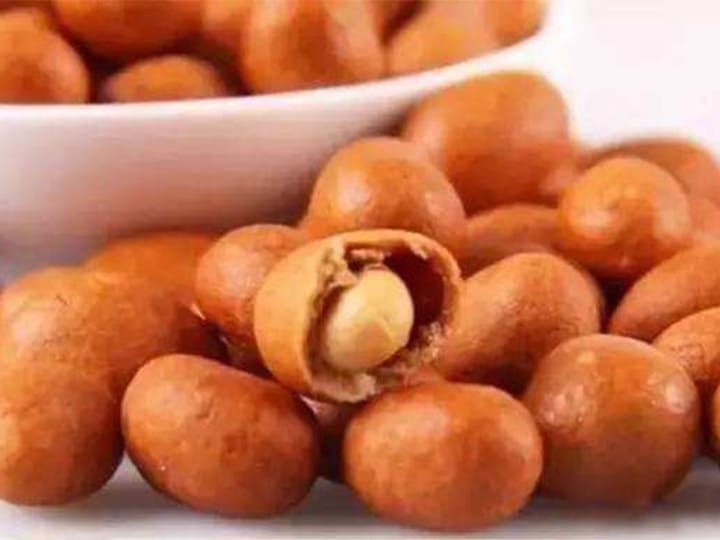

Die beschichtete Erdnussverarbeitungsanlage wird zur Herstellung von beschichteten Erdnüssen verwendet. Sie verwendet Erdnüsse als Rohmaterial und beschichtet dann geröstete, reife Erdnüsse außen mit einer Schicht Sirup oder Klebreismehl. Die von der beschichteten Erdnussverarbeitungsanlage hergestellten beschichteten Erdnüsse haben leuchtende Farben und eine glatte Röstung. Alle Erdnussverarbeitungsmaschinen zeichnen sich durch hohen Durchsatz, geringe Geräuschentwicklung, stabilen Betrieb und keine Umweltverschmutzung aus.

Zwei Sorten panierte Erdnüsse

Für panierte Erdnüsse gibt es zwei unterschiedliche Verarbeitungsmethoden: zum einen das Braten und zum anderen das Backen. Der Herstellungsprozess dieser beiden Arten von überzogenen Erdnüssen ist ungefähr gleich, die Erhitzungsmethode nach dem Überziehen ist jedoch unterschiedlich. Diese beiden Arten von überzogenen Erdnüssen haben unterschiedliche Geschmacksrichtungen. Geröstete, panierte Erdnüsse haben ein glattes Aussehen und einen knackigen Geschmack. Die frittierten, umhüllten Erdnüsse haben eine frostige Konsistenz und einen einzigartigen Geschmack.

Die beiden Arten von beschichteten Erdnüssen sind reich an Nährstoffen und enthalten eine Vielzahl von Vitaminen, die das menschliche Wachstum und die Entwicklung fördern, das Gedächtnis verbessern und die Alterung verzögern können.

Arbeitsvideo einer Verarbeitungslinie für beschichtete Erdnüsse

Automatische Verarbeitungslinie für beschichtete Erdnüsse

Erdnussröstmaschine – Erdnussschälmaschine – Überzugsmaschine – Schwenkofen – Kühlmaschine – Würzmaschine – Verpackungsmaschine

Erdnussröster

Mit dem Erdnussröster werden Erdnüsse zum Reifen geröstet. Der Erdnussröster eignet sich zum Rösten verschiedenster Rohstoffe und die einsetzbaren Heizquellen sind vielfältig. Der Einsatz dieses Trommelrösters kann die Bruchrate von Erdnüssen reduzieren. Die Maschine verfügt über eine große Produktionsleistung und einen hohen Wirkungsgrad.

Erdnussschälmaschine

Nach dem Rösten benötigen Sie einen trockenen Erdnussschäler, um die rote Erdnusshaut zu entfernen. Die Erdnussschälmaschine nutzt das Arbeitsprinzip der differenziellen Rollreibungsübertragung, um Erdnussschalen zu entfernen. Nachdem geröstete Erdnüsse in den durch den Reibsand gebildeten Schälbereich gelangen, werden Erdnusskerne und Erdnussschalen automatisch getrennt. Und durch den Einsatz dieser Maschine können vollständigere Erdnusskerne erhalten bleiben. Diese Maschine eignet sich zum Schälen von Erdnüssen nach dem Rösten. Handelt es sich um rohe Erdnüsse, benötigen Sie zum Schälen der Erdnüsse einen feuchten Erdnussschäler.

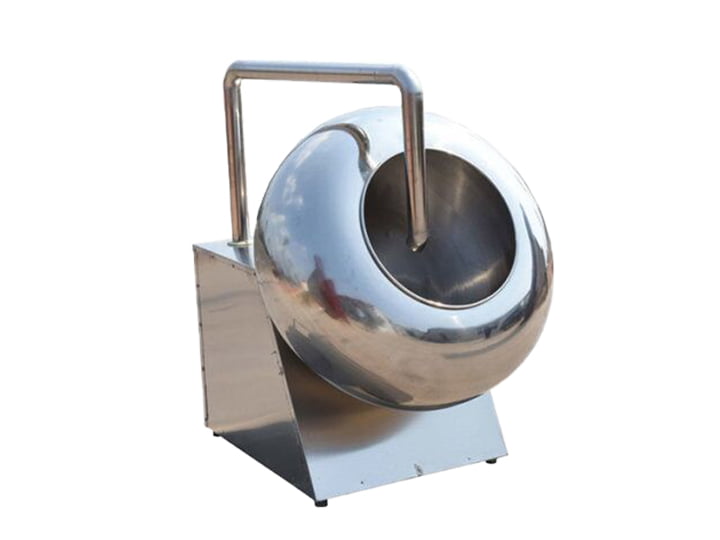

Erdnussbeschichtungsmaschine

Die Erdnussbeschichtungsmaschine ist eine Spezialausrüstung, die speziell zum Beschichten der Oberfläche von Erdnüssen verwendet wird. Die Beschichtungsmaschine wird vom Motor angetrieben, um den mit Zucker überzogenen Topfkörper zu drehen, und unter der Wirkung der Zentrifugalkraft rollt das Material im Topf auf und ab und reibt, um die mit Zucker überzogene Mischung zu erreichen. Die Oberfläche der von dieser Maschine verarbeiteten Erdnüsse ist glatt. Die Maschine zeichnet sich durch stabilen Betrieb, geringe Geräuschentwicklung, Sicherheit und Gesundheit aus.

Schwenkofen

Der Schwenkofen wird hauptsächlich zum Backen von körnigen Lebensmitteln wie Erdnüssen und Pistazien verwendet. Wenn die Maschine läuft, bleiben die Rohstoffe auf der horizontalen Backform. Die Backform bewegt sich in horizontaler Richtung, während der Boden erhitzt wird. Durch das Ausrollen auf dem Backblech wird das körnige Lebensmittel gleichmäßig erhitzt. Die im Schwenkofen gerösteten Erdnüsse haben eine glatte Oberfläche und verfärben sich nicht. Die Maschine zeichnet sich durch eine hohe Produktionseffizienz, eine geringe Lebensmittelzerkleinerungsrate und eine gleichmäßige Farbe aus.

Kühlmaschine

Nach dem Rösten die überzogenen Erdnüsse mit einem Kühler abkühlen lassen. Die Maschine besteht aus einem drehzahlgeregelten Antrieb, einer Kühlbox und einem Kühlgebläse. Der Motor treibt den Kühlventilator an, um die gerösteten Erdnüsse zu drehen.

Gewürzmaschine

Eine Würzsmaschine wird verwendet, um die beschichteten Erdnüsse und das Gewürz gleichmäßig zu mischen. Sie wird vom Motor angetrieben, um die Maschine in Rotation zu halten, damit die Rohstoffe und Gewürze gleichmäßig vermischt werden.

Pellet-Verpackungsmaschine

Der letzte Schritt der Verarbeitungslinie für beschichtete Erdnüsse besteht darin, die beschichteten Erdnüsse mit einer Pelletverpackungsmaschine zu verpacken. Diese Maschine eignet sich zum Verpacken von Getreide, getrockneten Lebensmitteln aller Art, medizinischen Materialien, Snacks und anderen körnigen Lebensmitteln. Die Verpackungsmaschine wird über ein Multifunktions-Bedienfeld gesteuert, mit dem das Verpackungsgewicht und die Anzahl der Verpackungsbeutel eingestellt werden können. Die Hauptteile bestehen aus Edelstahl und der Dichtungsteil besteht aus einem gut erhitzten Aluminiumblock. Es kann sich schnell erwärmen und hat eine gute Dichtwirkung. Darüber hinaus können wir die Maschine mit einem Codierer ausstatten, um je nach Kundenwunsch das Verpackungsdatum oder das Firmenlogo auf dem Verpackungsbeutel zu codieren.

Vorteile von Erdnussbeschichtungsmaschinen

1. Alle Maschinen in der Produktionslinie bestehen aus lebensmittelechtem Edelstahl, der langlebig und sicher zu verwenden ist.

2. Die Produktionslinie für beschichtete Erdnüsse kann einen kontinuierlichen Betrieb mit hoher Produktionseffizienz und großer Leistung realisieren, wodurch viele Personalressourcen eingespart werden können.

3. Die fertig beschichteten Erdnüsse zeichnen sich durch eine geringe Schadensrate, eine gleichmäßige Beschichtung und eine gute Farbe aus.

4. Wir können verschiedene Produktionspläne anpassen, um den unterschiedlichen Bedürfnissen der Kunden gerecht zu werden.

Hauptmaschinenparameter der Produktionslinie für beschichtete Erdnüsse

| Artikel | Parameter |

| Erdnuss-Röstmaschine | Modell: TZ-100 Leistung: 1,1 kW Elektrische Heizleistung: 18 kW Kapazität: 80kg-120kg/h Luftverbrauch: 3–6 kg Abmessungen: 3000*1200*1700mm Material: Edelstahl Vorteile: Energieeinsparung, Sicherheit, Hygiene, Komfort und einfache Bedienung. |

| Beschichtungsmaschine | Modell: TZ-1000 Geschwindigkeit: 28 U/min (variable Geschwindigkeit) Sendeleistung: 0,75 kW Lüfterleistung: 250 W Untere Heizleistung: 2 kW Heißluftleistung: 2 kW Kapazität: 80–180 kg/h Maschinengröße: 1200*1000*1700mm |

| Schwenkröstmaschine | Modell: TZ-2 Sendeleistung: 0,75 kW Heizleistung: 36 kW (Flüssiggasvolumen: 3 kg/h) Kapazität: 80–100 kg/h (20–45 kg/Charge) Größe der Schwenkplatte: 1200 x 1200 mm Abmessungen: 2400*2000*1350mm |

| Kühlbox | Lüfterleistung: 1,1 kW Spannung: 380 V 50 Hz Abmessungen: 1300*600*600mm |

| Gewürzmaschine | Modell: TZ-800 Kapazität: 100–300 kg/h Leistung: 1,1 kW Größe: 1000 * 800 * 1300 mm |

| Verpackungsmaschine | Beutelstil: Rückenversiegelung Verpackungsgeschwindigkeit: 32–72 Beutel/Minute oder 50–100 Beutel/Minute Beutellänge: 30–180 mm Beutelbreite: 25–145 mm (erster muss ersetzt werden) Füllbereich: 22–220 g Leistung: 1,8 kW Größe: 650*1050*1950mm |