กระบวนการทอดในอุตสาหกรรมอาหาร เหมาะสำหรับการทอดอาหารพองและของว่างทุกชนิด มันประกอบด้วยเครน, เครื่องทอดสายพานตาข่าย และเครื่องปรุงรส, เครื่องเป่าแห้ง และเครื่องบรรจุภัณฑ์ เครื่องจักรทั้งหมดสำหรับการประมวลผลอาหารทอดมีระดับอัตโนมัติสูง ประหยัดเวลาและพลังงาน.

รอก

รอกนี้เหมาะสำหรับการขนส่งและการเลือกอาหาร เครื่องมือวัดที่แม่นยำ อุปกรณ์ฮาร์ดแวร์ ตัวยึดต่างๆ และวัสดุที่เป็นผง โครงทำจากเหล็กคุณภาพสูงและตรงตามมาตรฐานแห่งชาติ การดำเนินการมีเสถียรภาพและเชื่อถือได้ และยังสามารถปรับแต่งได้ตามความต้องการของผู้ใช้

ข้อดีของรอก

1. รอกทำงานได้อย่างราบรื่นและมีเสียงรบกวนต่ำ

2. สายพานมีความยืดหยุ่นน้อยและไม่เสียรูปง่าย ในขณะเดียวกันก็บำรุงรักษาง่าย ซึ่งช่วยเพิ่มความสม่ำเสมอในการลำเลียงและเพิ่มประสิทธิภาพในการทำงานอย่างมาก

3. มันใช้การปรับความเร็วแบบไม่มีขั้นตอน และคุณสามารถปรับแต่งตามลักษณะของวัตถุดิบของคุณ ในกระบวนการทอดในอุตสาหกรรมอาหาร สายพานตาข่ายของเครนกว้าง 500 มม.

4. รอกมีโครงสร้างที่กะทัดรัดและระบบอัตโนมัติในระดับสูง มันมาแทนที่การใช้แรงงานหนัก ซึ่งช่วยประหยัดเวลาและพลังงานของคุณได้อย่างมาก

พารามิเตอร์ทางเทคนิค

| แบบอย่าง | TZ-2000 |

| วัสดุ | สแตนเลส304 |

| ความกว้างของสายพานตาข่าย | 500มม |

| กำลังมอเตอร์ | 0.55KW |

| มิติ | 1500*900*1030มม |

| เข็มขัดพียู | 800มม |

เครื่องทอดสายพานตาข่าย

หม้อทอดอาหารว่างเป็นสิ่งจำเป็นในกระบวนการทอดในอุตสาหกรรมอาหาร อุณหภูมิของน้ำมันถูกควบคุมโดยอัตโนมัติ และคุณสามารถตั้งค่าได้ตั้งแต่ 0 ถึง 230 องศา มันเหมาะสำหรับการทอดอาหารหลากหลายชนิด อาหารที่ผลิตจากกระบวนการนี้มีสีสันสดใส และช่วยแก้ปัญหาการเกิดกรดเกินขณะทอด ด้วยกล่องจ่ายไฟอิสระ การใช้งานจึงง่ายและปลอดภัย ความเร็วในการทำงานถูกควบคุมโดยการเปลี่ยนความถี่ ซึ่งช่วยประหยัดแรงงานและทำให้ผลิตภัณฑ์มีสีและรสชาติเดียวกัน.

นอกจากนี้ หม้อทอดอาหารขบเคี้ยวยังกำหนดค่าระบบกรองการไหลเวียนซึ่งรวมถึงตัวกรองหยาบ ปั๊มหมุนเวียนที่อุณหภูมิสูง และท่อ ฯลฯ หม้อทอดแบบสายพานตาข่ายรวมการป้อนอัตโนมัติ การคายประจุ การควบคุมอุณหภูมิ การขูดตะกรันและการกรองโดยรวม

พารามิเตอร์ทางเทคนิค (เครื่องทำความร้อนไฟฟ้า)

| แบบอย่าง | ขนาด (มม.) | น้ำหนัก (กก.) | กำลัง (กิโลวัตต์) | ความจุ(กก./ชม.) | ความกว้างของสายพานตาข่าย (มม.) |

| TZ-2000 | 2200*1000*1800 | 300 | 36 | 300 | 800 |

| TZ-3500 | 3500*1200*2400 | 1000 | 80 | 500 | 800 |

| TZ-4000 | 4000*1200*2400 | 1200 | 100 | 600 | 800 |

| TZ-5000 | 5000*1200*2400 | 1500 | 120 | 800 | 800 |

| TZ-6000 | 6000*1200*2400 | 1800 | 180 | 1000 | 800 |

| TZ-8000 | 8000*1200*2600 | 2000 | 200 | 1500 | 800 |

พารามิเตอร์ทางเทคนิค (การทำความร้อนด้วยแก๊ส)

| แบบอย่าง | ขนาด (มม.) | น้ำหนัก (กก.) | กำลัง(กิโลแคลอรี) | ความจุ(กก./ชม.) |

| TZ-3500 | 3500*1200*2400 | 1200 | 300,000 | 500 |

| TZ-4000 | 4000*1200*2400 | 1500 | 500,000 | 600 |

| TZ-5000 | 5000*1200*2400 | 1700 | 600,000 | 800 |

ข้อดีของหม้อทอดแบบสายพานตาข่าย

1. สายพานลำเลียงสองชั้นพร้อมมีดโกน สายพานตาข่ายถักแบบเกลียวสามารถยกขึ้นพร้อมกับตัวยึดโดยรวมได้ ซึ่งสะดวกสำหรับการทำความสะอาดสุขอนามัยภายในของถังน้ำมัน มีทั้งแบบยกโซ่มอเตอร์และแบบยึดสายพานแบบตาข่ายซึ่งสามารถยกเครื่องได้อย่างรวดเร็วและมีความสูงประมาณ 450 มม.

2. ความหนาของกระดานถังน้ำมันคือ 3 มม. พร้อมฉนวนสองชั้น วัสดุฉนวนคือ 5 ซม. พร้อมแผ่นอะลูมิเนียมซิลิเกต ตัวป้องกันตัวเครื่องทำจากแผ่นเย็นสแตนเลสปัดเงา 0.8 มม.

3. มีระบบขูดตะกรันอัตโนมัติที่ด้านล่างของถังน้ำมันจึงไม่มีสิ่งตกค้าง ระบบกรองอัตโนมัติภายนอกช่วยให้สารตกค้างที่แขวนลอยอยู่ในชั้นน้ำมันถูกกรองลงในตัวกรองน้ำมัน

4. มีเกราะป้องกันบนถังน้ำมันเพื่ออำนวยความสะดวกในไอเสียควันน้ำมันและไอน้ำ ทั้งหมดทำจากแผ่นสแตนเลสขัดเงา 1.0 มม.

5. พลังงานความร้อนของท่อความร้อนไฟฟ้าคือ 72kw และสามารถควบคุมอุณหภูมิได้โดยอัตโนมัติด้วยการควบคุมความเร็วในการแปลงความถี่

6. ท่อทำความร้อนไฟฟ้าได้รับการออกแบบให้เป็นรูปทรง "Z" ซึ่งควบคุมในสามขั้นตอนตรงกลางของสายพานตาข่ายด้านล่างเพื่อปรับปรุงผลการทอด

เครื่องปรุงรสแบบถังต่อเนื่อง

เครื่องปรุงรสแบบกลองแบบต่อเนื่องคือการเพิ่มเครื่องปรุงรสลงในอาหารทอด โดยผสมผสานการผสมและการระบายเครื่องปรุงรสอัตโนมัติโดยรวม ซึ่งใช้กันอย่างแพร่หลายในสายการผลิตอาหารต่อเนื่องขนาดใหญ่ ที่สำคัญสามารถผสมอาหารทอดและเครื่องปรุงรสได้อย่างสม่ำเสมอ

พารามิเตอร์ทางเทคนิค

| แบบอย่าง | ขนาด(มิลลิเมตร) | น้ำหนัก (กก.) | พลัง | ความจุ |

| CY2400 | 2400*1000*1500 | 300 | 0.75 | 1,000กก./ชม |

| CY3000 | 3000*1000*1600 | 380 | 1.1 | 1500กก./ชม |

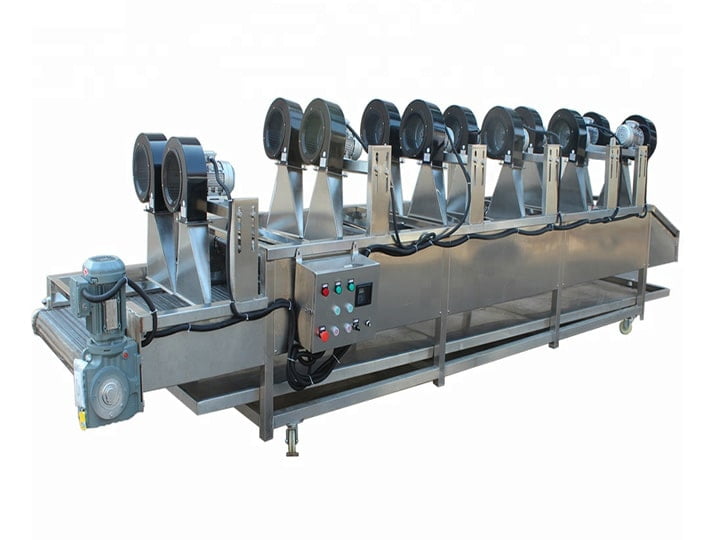

เครื่องอบแห้งด้วยลม

ในกระบวนการทอดในอุตสาหกรรมอาหาร เครื่องเป่าแห้งจะทำให้แห้งอาหารทอดอย่างเต็มที่เพื่อความสะดวกในการบรรจุภัณฑ์ มีพัดลมหลายตัวบนเครื่อง และจำนวนของพวกมันสามารถปรับแต่งได้ อาหารทอดทั้งหมดสามารถทอดได้อย่างสม่ำเสมอภายในเวลาสั้นๆ นอกจากนี้ คุณสามารถปรับมุมของพัดลมเพื่อการทำให้แห้งที่ดียิ่งขึ้น.

พารามิเตอร์ทางเทคนิค

| แบบอย่าง | TZ-510 | ทีเอ-520 |

| ความกว้างของสายพานตาข่าย | 1,000มม | |

| โหมดการปรับความเร็ว | การปรับความเร็วด้วยตนเอง | การปรับความเร็วด้วยตนเอง |

| จำนวนแฟน | แฟนๆ 12 คน | แฟนๆ 10 คน |

| พลัง | 12KW, 380V / 50Hz | 7.5KW,380V / 50Hz |

| วัสดุ | สแตนเลสเกรดอาหารคุณภาพสูง | สแตนเลสเกรดอาหารคุณภาพสูง |

| ความหนาของแผ่นยึดพัดลม | 2มม | |

| ขนาด | 6000×1700×1500 | 3500x1200x1400มม |

เครื่องบรรจุ

เครื่องบรรจุเป็นขั้นตอนสุดท้าย และเรามักจะใช้เครื่องบรรจุสิบถังเพื่อบรรจุ เมื่อเทียบกับเครื่องบรรจุอื่นในตลาด เครื่องนี้มีความแม่นยำสูงกว่า มีการใช้งานที่หลากหลายและสามารถบรรจุอาหารพองหรือของว่างอื่นๆ ได้ทุกชนิด

พารามิเตอร์ทางเทคนิค

| น้ำหนักสูงสุด | 1,000ก |

| ช่วงการชั่งน้ำหนักเดี่ยว | 10-1000 ก |

| ความแม่นยำในการชั่งน้ำหนัก | ±0.3~1.5 ก |

| ความสามารถในการชั่งน้ำหนัก | สูงสุด 3,000cc |

| ความเร็วในการชั่งน้ำหนัก | 60 ครั้ง/นาที |

| แอปพลิเคชัน | อาหาร 50 ชนิด |

| ส่วนประกอบควบคุม | หน้าจอปุ่มขนาด 8.4 นิ้ว |