The frying process in food industry is suitable for deeply frying all kinds of puffed food and other snacks. It includes a hoist, mesh belt frying machine and seasoning machine, air drying machine, and packing machine. The whole fried food processing machine has a high degree of automatic, saving time and energy.

Hoist

The hoist is suitable for the transportation and selection of various foods, precision instruments, hardware accessories, various fasteners, and powder materials. The frame is made of high-quality steel and meets national standards. The operation is stable and reliable, and can also be customized according to user requirements.

The advantages of hoist

1. The hoist runs smoothly with low noise.

2. The belt has small elasticity and is not easy to deform. Meanwhile, it is easy to maintain, which enhances the consistency of conveying and greatly improves its work efficiency.

3. It adopts step-less speed regulation, and you can customize according to the feature of your raw material. In the frying process in food industry, the mesh belt of the hoist is 500mm in width.

4. The hoist has a compact structure and a high degree of automation. It replaces heavy manual labor, greatly saving your time and energy.

Technical parameter

| Model | TZ-2000 |

| Material | 304 stainless steel |

| The width of the mesh belt | 500mm |

| Motor power | 0.55KW |

| Dimension | 1500*900*1030mm |

| PU belt | 800mm |

Mesh belt fryer

A snack food deep fryer is essential in the frying process in food industry. The oil temperature is automatically controlled, and you can set it free from 0 to 230 degrees. It is suitable for frying various foods. The food produced by this machine process is bright in color, and it solves the problem of excessive acidification during frying. With an independent power distribution box, the operation is simple and safe. The running speed is controlled by frequency conversion, which saves manpower and ensures that the product has the same color and taste.

In addition, the snack food deep fryer configures the circulation filtration system, which includes coarse filters, high-temperature circulation pumps, and pipelines, etc. Mesh belt fryer integrates automatic feeding, discharging, temperature control, slag scraping, and filtering as a whole

Technical parameter (electric heating)

| Model | Dimension(mm) | Weight(kg) | Power(kw) | Capacity(kg/h) | Mesh belt width(mm) |

| TZ-2000 | 2200*1000*1800 | 300 | 36 | 300 | 800 |

| TZ-3500 | 3500*1200*2400 | 1000 | 80 | 500 | 800 |

| TZ-4000 | 4000*1200*2400 | 1200 | 100 | 600 | 800 |

| TZ-5000 | 5000*1200*2400 | 1500 | 120 | 800 | 800 |

| TZ-6000 | 6000*1200*2400 | 1800 | 180 | 1000 | 800 |

| TZ-8000 | 8000*1200*2600 | 2000 | 200 | 1500 | 800 |

Technical parameter (gas heating)

| Model | Dimension(mm) | Weight(kg) | Power(kcal) | Capacity(kg/h) |

| TZ-3500 | 3500*1200*2400 | 1200 | 300,000 | 500 |

| TZ-4000 | 4000*1200*2400 | 1500 | 500,000 | 600 |

| TZ-5000 | 5000*1200*2400 | 1700 | 600,000 | 800 |

Advantages of mesh belt fryer

1. Double-layer conveyor belt with a scraper. The spiral braided mesh belt can be lifted up with the bracket as a whole, which is convenient for cleaning the internal sanitation of the oil tank. There are motor chain lifting and mesh belt bracket types, which can lift the machine quickly, and the height is about 450mm.

2. The thickness of the oil tank board is 3mm with double-layer insulation. The insulation material is 5cm with an aluminum silicate board. The shell guard is made of a 0.8mm brushed stainless steel cold plate.

3. There is an automatic slag scraping system at the bottom of the oil tank, so there is no residue to remain. An external automatic filtering system allows the residue suspended in the oil layer to be filtered into the oil filter.

4. There is a shield on the oil tank to facilitate the exhaust of oil smoke and steam. The whole is made of 1.0mm brushed stainless steel plate.

5. Electric heating tube heating power is 72kw, and it can control the temperature automatically with frequency conversion speed regulation.

6. The electric heating tube is designed as a “Z” shape, which is controlled in three stages in the middle of the lower mesh belt to improve the frying effect.

Continuously drum type seasoning machine

The continuous drum type seasoning machine is to add the seasonings on the fried food, It integrates automatic seasoning mixing and discharging as a whole, widely applying to the large-scale continuous food production lines. Most importantly, it can mix the fried food and seasoning evenly.

Technical parameter

| Model | Size(mm) | Weight(kg) | Power | Capacity |

| CY2400 | 2400*1000*1500 | 300 | 0.75 | 1000kg/h |

| CY3000 | 3000*1000*1600 | 380 | 1.1 | 1500kg/h |

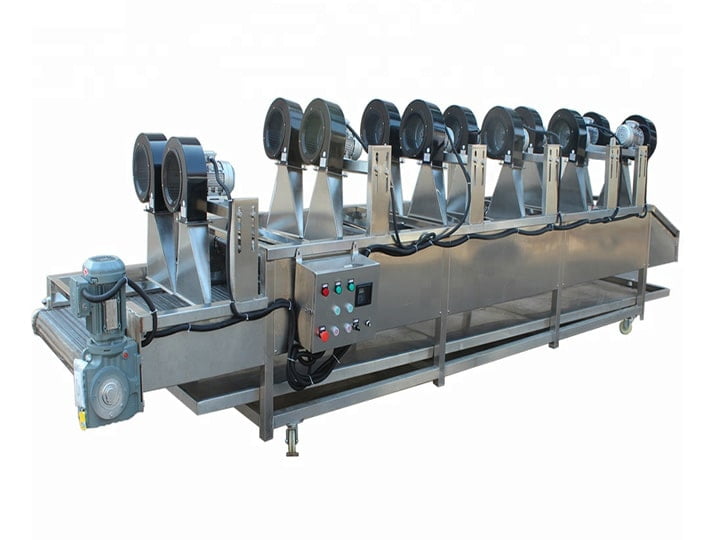

Air drying machine

In frying processing in food industry, the air drying machine is to fully dry the fried food for easy packing. There are several fans on the machine, and the number of them can be customized. All the fried food can be fried evenly within a short time. What’s more, you can adjust the angle of fans for better drying.

The technical parameter

| Model | TZ-510 | TA-520 |

| Mesh belt width | 1000mm | |

| The Speed adjustment mode | manual speed adjustment | manual speed adjustment |

| Number of fans | 12 fans | 10 fans |

| Power | 12KW, 380V / 50Hz | 7.5KW,380V / 50Hz |

| Material | high-quality food-grade stainless steel | high-quality food-grade stainless steel |

| The thickness of fan fixing plate | 2mm | |

| Size | 6000×1700×1500 | 3500x1200x1400mm |

Packing machine

The packing machine is the last step, and we usually use ten-bucket packing machine to pack them. Compared with another packing machine on the market, it bears higher precision. It has wide application and can pack all kinds of puffed food or other snacks.

Technical parameter

| Maximum weight | 1000g |

| Single weighing range | 10-1000 g |

| Weighing accuracy | ±0.3~1.5 g |

| Weighing capacity | Maximum 3000cc |

| Weighing speed | 60 times / minute |

| Application | 50 kinds of food |

| Control components | 8.4 inch button screen |