The chicken popcorn production line includes a set of automatic production machines to make chicken popcorn, fish popcorn. It mainly includes cutting, battering, drum-breading machines, frying, air-drying machine, and other machines to make chicken popcorn. The chicken popcorn production line is suitable for meat, aquatic products, vegetables, cheese, and their mixtures.

Above is a short introduction, how to make chicken popcorn? Let me introduce you machine one by one to show you the whole process.

About fried chicken popcorn

Fried chicken popcorn is usually a deep-fried snack made by dicing chicken breast and then marinating and deep-frying. The fried popcorn chicken has the appearance of golden scales and a crispy taste. It is usually eaten with tomato sauce and other sauces. Fried chicken popcorn can not only be eaten as a staple food, it can also be eaten as a snack.

Fried chicken popcorn VS baked chicken popcorn

The fried chicken popcorn is made by frying the chicken popcorn after the steps of marinating, battering, breading. The roasted chicken popcorn is baked in the oven to make the chicken popcorn mature.

Compared to fried type, roasted chicken popcorn have very little oil. And it’s also very delicious. Therefore, roasted chicken popcorn is more suitable for people who exercise or lose weight. The craftsmanship of these two kinds of chicken popcorn is roughly similar. You can choose different maturation methods according to the finished product you need.

The chicken popcorn production line process

The production process of chicken popcorn is cutting, pickling, sizing, flouring, frying, and cooling. In the commercial chicken popcorn production line, each step corresponds to the chicken popcorn production machine for mass production.

Cutting machine

The cutting machine can efficiently and quickly cut the chicken breast into pieces. The machine meets the food production standards. The cut size can be customized according to customer requirements.

Belt conveyor

The belt conveyor adopts 304 material. The structure is simple, easy to maintain, transported material efficiently, and meets mass production. The machine length and belt width can be customized according to the customer’s requirement.

Battering machine

The battering machine is mainly for spreading the batter on the popcorn evenly in the chicken popcorn production line. It can complete the battering automatically, when the chicken popcorn passes through the upper and lower mesh belt, the machine will spray the batter on chicken popcorn evenly. After battering, the chicken popcorn is exposed to a wind shower system to avoid excessive slurry, then entering the next process.

Drum breading machine

The drum breading machine wraps a layer of powder on the surface of the chicken popcorn by the rotation of the roller, which is suitable for chicken popcorn, chicken, fish pieces, etc.; the design of the drum makes the coated evenly, even the folds and bumps of the product can evenly coat.

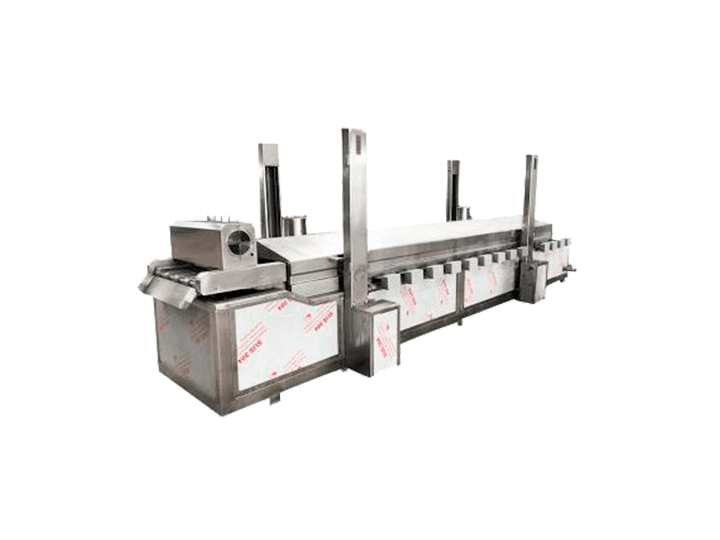

Mesh belt frying machine

The continuous mesh belt frying machine is important in the chicken popcorn production line. The frying machine equips with an independent electric control box, which is easy to operate; the running speed of the mesh belt can be adjusted to keep the color of the fried food bright.

Air drying machine

The air dryer can effectively remove the oil on the surface of the material and improve the degree of automation of food processing; the air-drying is normal temperature, which effectively protects the color and quality of the material surface.

400kg/h popcorn chicken processing line parameters

| Number | Machine name | Parameter |

| 1 | Chicken popcorn cutting machine | Model:TZ-450 Size:1700*900*1450mm Power:2.2kw Belt width:450mm Machine material:304 |

| 2 | Belt converyor | Model:TZ-500 Size:1500*600*1000mm Power:0.55kw Belt width:500mm Machine material:304 |

| 3 | Chicken popcorn battering machine | Model:TZ-400 Size:3020*880*1250mm Power:1.3kw Belt width:400mm Machine material:304 Capacity:400kg/h |

| 4 | breading machine | Model:TZS-400 Size:4660*1500*2400mm Power:2.45kw Belt width:400mm Machine material:304 Capacity:400kg/h |

| 5 | Chicken & fish popcorn frying machine | Model: TZ-800 Size:4500*1100*1200mm Power:124kw(electric) Belt width:800mm Machine material:304 Capacity:500kg/h |

| 6 | Cooling machine | Model: TZS-800 Size:6000*1100*1100mm Power:8kw Belt width:800mm Machine material:304 |

Highlights of the chicken popcorn production plant

- All the chicken popcorn production machines are made of stainless steel and other food-specific materials. It has the characteristics of meeting safety and sanitation standards and easy cleaning and maintenance.

- The chicken popcorn production line is multi-purpose, applicable to a wide range of raw materials. And the produced products have the characteristics of good taste and strong meat texture.

- All fish popcorn-making machines are easy to operate and highly automated and are widely used in food processing plants.

- The machine in this automated production line is not only suitable for the production of chicken popcorn. It is also widely used for the production of chicken steak, fish steak, lotus root, and other fried foods.

- The frying machine, cooling machine, and conveyor belt in the chicken popcorn production plant can be customized according to customer needs. And all the chicken popcorn-making machines have multiple models. Therefore, the production line can meet the needs of different customers.