Die Hamburger-Patties-Maschine eignet sich zur Formung verschiedener Patties und Gemüse-Patties. Durch den Austausch der Formen in unterschiedlichen Größen und Formen können Produkte mit verschiedenen Spezifikationen hergestellt werden. Es handelt sich um spezielle Ausrüstung zur Lebensmittelverarbeitung. Sie ist geeignet für jeden Metzger, Delikatessenladen, kleinen Supermarkt, Café, Takeaway usw. Die Burger-Patties-Maschine kann mit einer automatischen Produktionslinie sowie mit einer Paniermaschine, einer Brotmaschine und einer Frittiermaschine kombiniert werden.

Kommerzielle Hamburger-Patty-Maschinenanwendung

Denn die Hamburger-Patty-Maschine kann die Schleifwerkzeuge ersetzen, um Produkte unterschiedlicher Form und Größe herzustellen. Und auch seine Rohstoffe sind sehr breit gefächert. Somit hat die Burger-Patty-Maschine ein breites Einsatzspektrum. Seine Rohstoffe können Huhn, Rind, Schwein, Lamm, Fisch, Garnelen, Kartoffeln, Kürbis, Karotten, grüne Bohnen usw. sein. Die Endprodukte können Hamburgerpastetchen, Fischfrikadellen, vegetarische Pastetchen, Kartoffelfrikadellen, Kürbiskuchen und Gemüsehamburger sein und andere Produkte.

Video zur Funktionsweise der Hamburger-Patty-Maschine

Die automatische Hamburger-Patty-Maschine technisch

| Fördergeschwindigkeit | 35 Stück/Min |

| Leistung | 0,55 kW |

| Geschwindigkeit des Maschenbandes | 130mm |

| Dimension | 860*600*1400mm |

| Gewicht | 100kg |

| Kapazität | 50-100kg/h |

Funktionsprinzip der Burger-Patty-Maschine

Die automatische Hamburger-Patty-Maschine kann das Befüllen, Formen, Kleben und Entladen von Materialien automatisch abschließen. Dabei arbeiten das Zuführpaddel und die Formtrommel synchron, sodass das Material automatisch in die Form der Maschine gefüllt werden kann. Die Fleischfüllung bildet sich in der Form und wird beim Drehen nach unten automatisch geformt und ausgeworfen. Das Formteil kann als Ganzes zerlegt werden, sodass die Dicke der Pastetchen sehr bequem angepasst werden kann.

Die Vorteile der automatischen Burger-Patty-Maschine

- Die Formmaschine besteht aus Edelstahl 304, die Form kann je nach Kundenwunsch angepasst werden;

- Die Maschine füllt und schneidet automatisch und entspricht den Hygienestandards für die Lebensmittelproduktion.

- Die Fördergeschwindigkeit beträgt 35 Stück/min, die Formgröße und das Gewicht sind gleichmäßig und die Farbe des Bratens ist nach Beginn des Frittiervorgangs hell;

- Es kann eine Vorrichtung hinzugefügt werden, um Wachspapier unter die Hamburger-Patties zu legen, um zu verhindern, dass die Patties beim Stapeln oder Verpacken kleben bleiben.

- Es eignet sich für eine Vielzahl von Rohstoffen und kann zur Herstellung von Fleischpasteten, Wasserprodukten, Obst und Gemüse verwendet werden.

- Die automatische Patty-Formmaschine kann Hamburger-Patties entsprechend dem eingestellten Gewicht herstellen.

- Die Burger-Patty-Formmaschine zeichnet sich durch schnelle Produktion, stabile Struktur und einfache Wartung aus.

Vorsichtsmaßnahmen für die Verwendung der Hamburger-Patty-Maschine

1. Überprüfen Sie zunächst die folgenden Teile der Maschine: ob die Drähte und mechanischen Teile locker sind; ob sich Butter im Schmierölbecher befindet; ob die Schutzabdeckung angebracht ist.

2. Die Hamburger-Patty-Maschine sollte auf einem flachen Tisch aufgestellt werden.

3. Stecken Sie vor dem Gebrauch den Netzstecker in die Steckdose und verwenden Sie dreiphasigen Strom. Und prüfen Sie, ob sich Verunreinigungen in der Maschine befinden.

4. Schalten Sie den Netzschalter ein. Nachdem die Kontrollleuchte aufleuchtet, kann die Maschine normal laufen.

5. Nach dem Einschalten des Geräts beginnt es mit der Zeitmessung und die Daten werden durch Drücken der Löschtaste automatisch gelöscht.

Endgültige Produktshow

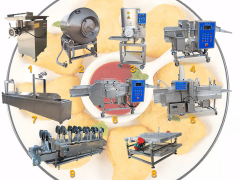

Verwandte Maschinen mit der Burger-Patty-Formmaschine

Um den Produktionsanforderungen großer Patty-Hersteller gerecht zu werden, bieten wir auch eine Burger-Patty-Produktionslinie an. Die Produktionslinie umfasst eine Schlichtemaschine, eine Bemehlungsmaschine, eine Eindickmaschine, eine Trommelbemehlungsmaschine, eine Kleiezuführmaschine, eine Bratmaschine und andere Maschinen. Die Burger-Patty-Produktionslinie kann die Arbeit des Sortierens, Bemehlens, Bratens, Frittierens usw. automatisch abschließen. Sie erfüllt die Produktionsanforderungen der meisten Fertigprodukte.

Automatische Hamburger-Patty-Maschine, exportiert auf die Philippinen

Ein Kunde aus den Philippinen wollte Rindfleisch-Patties zubereiten. Sein Rinderfrikadellen haben einen Durchmesser von 110 mm und eine Dicke von 20 mm. Wir haben zwei Maschinenmodelle. Einer kann einen maximalen Durchmesser von 100 mm und eine Dicke von 18 mm produzieren, der andere kann einen maximalen Durchmesser von 135 mm und eine Dicke von 20 mm produzieren. Auf Wunsch des Kunden empfehlen wir ihm den Einsatz einer großen Beef-Burger-Maschine. Die Burger-Fleischmaschine hat ein größeres Modell. Wenn Sie kleinere Größen herstellen, können Sie zwei oder drei Modelle in einer Reihe herstellen. Daher kann die Hamburger-Pastetchenmaschine mehrere Pastetchen gleichzeitig produzieren, was die Produktionsleistung steigern kann.

Der Kunde verlangte nicht nur runde Rindfleischfrikadellen, sondern wollte auch, dass wir die Form entsprechend der Form und Größe der von ihm bereitgestellten Zeichnungen anpassen. Wir können die Bedürfnisse dieses philippinischen Kunden voll und ganz erfüllen. Darüber hinaus verfügt unsere Burger-Patty-Maschine auch über eine automatische Abfallreinigungsvorrichtung. Im Vergleich zur manuellen Abfallreinigung ist die Abfallreinigung bequemer und spart Kunden Zeit. Da das Rohmaterial des Kunden Rindfleisch ist, das mehr Ballaststoffe enthält, empfehlen wir diese Maschine, die überschüssige Ballaststoffe und Abfall automatisch entfernen kann. Der Kunde war mit unseren Maschinen und dem professionellen Verkauf sehr zufrieden und gab bald eine Bestellung auf.