What is a Popcorn Production Line?

A popcorn production line is an automated equipment system for industrial popcorn production, covering corn popping, cooling, sorting, and packaging. It features high efficiency, automation, energy saving, and stable product quality. It can produce popcorn in various flavours and shapes, suitable for food processing factories, snack manufacturers, cinemas, and export-oriented enterprises.

How is Popcorn Produced?

Corn Preparation

- Select suitable corn varieties for popcorn, clean impurities, and ensure the raw material is clean, with a moisture content of about 13–15%.

Heating and Popping

- Pour an appropriate amount of oil into the cleaned popping pan, turn on the power, and press the start button to preheat the pan. Once it reaches the required temperature, add the corn kernels. The machine automatically stirs to ensure even heating. Through high heat and hot air circulation, the corn kernels quickly pop into popcorn. After 5–15 minutes, the popcorn is ready. If flavouring is needed, seasonings can be added directly according to the recipe.

Cooling

- Transport the freshly popped popcorn to the cooling area using a cooling conveyor. Fans quickly lower the temperature to maintain crispness and reduce the sticking of sugar or seasonings.

Screening and Grading

- Use a rotary screening machine to remove unpopped kernels, husks, and small fragments, ensuring the finished popcorn is visually appealing and of stable quality.

Packaging

- Popcorn can be packaged in bags, cans, or other forms. We provide fully automatic packaging machines for both bagging and filling, and can also include machines for printing production dates.

Popcorn Production Line Working Video

Main Equipment of a Popcorn Production Line

Popcorn Making Machine

Industrial popcorn machines feature automatic temperature control, automatic stirring, and automatic oil discharge. Using electromagnetic heating can save energy.

| Machine model | TZ-CZ90XJB-DC |

| Machine size | 1380*1610*1590mm |

| Effective working size | φ900mm |

| Total Weight | 600kg |

| Power | 43kw |

| Electric supply | 380V 50HZ |

Cooling Conveyor

This conveyor transfers the popped popcorn from the pan to the rotary drum sifter for cooling. The conveyor belt is made of stainless steel with evenly distributed holes, and the belt speed is adjustable.

| Machine model | TZ-WS60/700 |

| Machine size | 7200×1050×1610mm |

| Effective working size | 6900×550mm |

| Power | 1.2 KW |

| Electric supply | 380V 50HZ |

Rotary Drum Sifter

This machine uses a belt drive to prevent slipping. Popcorn is conveyed in a spiral manner, filtering out unpopped kernels, husks, and other small residues.

| Machine model | WS90/260 |

| Machine size | 2900×1100×1870mm |

| Effective working size | φ900×2700mm |

| Power | 0.55KW |

Automatic Popcorn Packaging Machine

This packaging machine can automatically weigh, bag, fill, seal, cut, detect faults with alarms, and print codes or inkjet markings. It also supports optional components such as nitrogen filling, dust removal, and automatic feeding systems.

| Specification | Details |

|---|---|

| Bag Style | Back Seal / Three-side Seal |

| Packing Speed | 20–80 bags/min |

| Power Consumption | 2.2 kW |

| Machine Weight | 420 kg |

| Dimensions | 750 × 750 × 2100 mm |

Why Choose a Popcorn Processing Line?

- High Efficiency and Output: Automated production with a daily output of 2–4 tons or more, saving time.

- Automated Operation: Temperature control, stirring, discharging, flavouring, and packaging are all automatic.

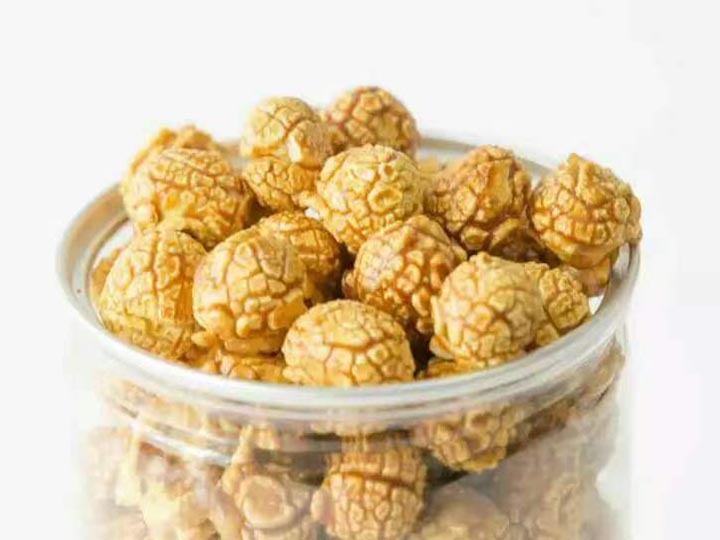

- Stable Product Quality: Even popping, uniform coating, crisp texture, and attractive appearance.

- Variety of Flavours: Supports original, caramel, chocolate, fruit, coconut, and more.

- Multiple Shape Options: Can produce ball, mushroom, snowflake, and other popcorn shapes.

- Energy Saving and Eco-Friendly: Uses electromagnetic heating or efficient hot air circulation to reduce energy consumption and noise.

- Lower Production Costs: High popping rate and raw material utilisation, with reduced labour input.

- Wide Application: Suitable for food processing factories, snack manufacturers, cinemas, theme parks, and export-oriented enterprises.

Customize Your Popcorn Production Solution with Taizy

By partnering with Taizy, you can design a popcorn production line tailored to your factory size, capacity needs, and product flavours. Whether for small-scale trial production or a large automated factory, Taizy provides a one-stop solution—from equipment selection and process design to installation and commissioning—ensuring efficient and stable production to meet diverse market demands. Contact us now to start your smart popcorn production journey.