Die Hähnchen-Popcorn-Produktionslinie umfasst eine Reihe von automatischen Produktionsmaschinen zur Herstellung von Hähnchen-Popcorn, Fisch-Popcorn. Sie umfasst hauptsächlich Zerkleinerungs-, Beschichtungs-, Drum-Breading-Maschinen, Frittieren, Lufttrocknungsmaschine und weitere Maschinen zur Herstellung von Hähnchen-Popcorn. Die Hähnchen-Popcorn-Produktionslinie ist geeignet für Fleisch, Meeresprodukte, Gemüse, Käse und deren Mischungen.

Oben finden Sie eine kurze Einführung: Wie macht man Hühnchen-Popcorn? Lassen Sie mich Ihre Maschine einzeln vorstellen, um Ihnen den gesamten Prozess zu zeigen.

Über frittiertes Hühnchen-Popcorn

Gebratenes Hühnchen-Popcorn ist normalerweise ein frittierter Snack, der aus Hähnchenbrust in Würfel geschnitten, dann mariniert und frittiert wird. Das frittierte Popcorn-Hähnchen hat das Aussehen goldener Schuppen und einen knusprigen Geschmack. Es wird normalerweise mit Tomatensauce und anderen Saucen gegessen. Gebratenes Hühnchen-Popcorn kann nicht nur als Grundnahrungsmittel, sondern auch als Snack verzehrt werden.

Gebratenes Hühnchen-Popcorn vs. gebackenes Hühnchen-Popcorn

Das frittierte Hühnchen-Popcorn wird durch Frittieren des Hühnchen-Popcorns nach den Schritten Marinieren, Panieren und Panieren hergestellt. Das geröstete Hühnchen-Popcorn wird im Ofen gebacken, damit das Hühnchen-Popcorn reift.

Im Vergleich zu frittiertem Popcorn enthält gebratenes Hühnchen-Popcorn sehr wenig Öl. Und es ist auch sehr lecker. Daher ist gebratenes Hühnchen-Popcorn eher für Menschen geeignet, die Sport treiben oder abnehmen. Die Verarbeitung dieser beiden Arten von Hühnchen-Popcorn ist im Großen und Ganzen ähnlich. Je nach gewünschtem Endprodukt können Sie verschiedene Reifungsmethoden wählen.

Der Prozess der Hühnchen-Popcorn-Produktionslinie

Der Herstellungsprozess von Hühnchen-Popcorn umfasst das Schneiden, Einlegen, Sortieren, Bemehlen, Braten und Abkühlen. In der kommerziellen Hühnchen-Popcorn-Produktionslinie entspricht jeder Schritt der Hühnchen-Popcorn-Produktionsmaschine für die Massenproduktion.

Schneidemaschine

Die Schneidemaschine kann die Hähnchenbrust effizient und schnell in Stücke schneiden. Die Maschine entspricht den Lebensmittelproduktionsstandards. Die Schnittgröße kann je nach Kundenwunsch angepasst werden.

Förderband

Der Bandförderer besteht aus 304-Material. Die Struktur ist einfach, leicht zu warten, transportiert das Material effizient und eignet sich für die Massenproduktion. Die Maschinenlänge und Bandbreite können je nach Kundenwunsch individuell angepasst werden.

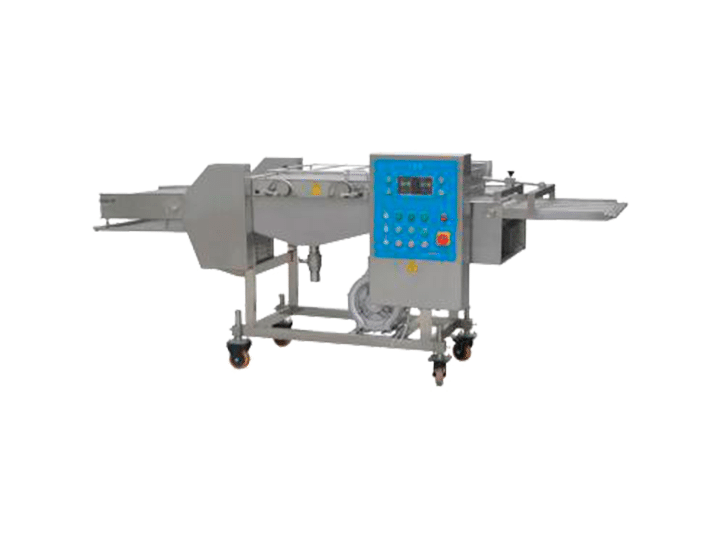

Schlagmaschine

Die Beschichtungsmaschine dient hauptsächlich dem gleichmäßigen Auftragen der Panade auf das Popcorn in der Hähnchen-Popcorn-Produktionslinie. Sie kann die Panade automatisch auftragen, wenn das Hähnchen-Popcorn über das obere und untere Maschenband läuft, wird die Maschine die Panade gleichmäßig auf das Hähnchen-Popcorn sprühen. Nach dem Beschichten wird das Hähnchen-Popcorn einem Windduschsysteem ausgesetzt, um zu starke Rückstände zu vermeiden, und tritt dann in den nächsten Prozess ein.

Trommelpaniermaschine

Die Trommelpaniermaschine wickelt durch die Drehung der Walze eine Pulverschicht auf die Oberfläche des Hühnchen-Popcorns, die für Hühnchen-Popcorn, Hühnchen, Fischstücke usw. geeignet ist; Das Design der Trommel sorgt für eine gleichmäßige Beschichtung, sodass selbst Falten und Unebenheiten des Produkts gleichmäßig beschichtet werden können.

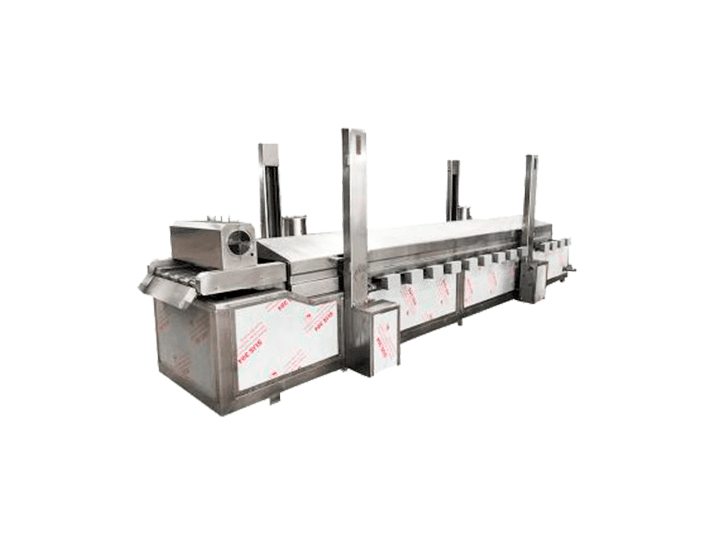

Frittiermaschine mit Netzband

Die kontinuierliche Mesh-Belt-Frying-Maschine ist in der Hähnchen-Popcorn-Produktionslinie wichtig. Die Fritteuse ist mit einer eigenen elektrischen Schalttafel ausgestattet, die Bedienung ist einfach; die Laufgeschwindigkeit des Mesh-Belts kann angepasst werden, um die Farbe des frittierten Produkts hell zu halten.

Lufttrocknungsmaschine

Der Lufttrockner kann das Öl auf der Oberfläche des Materials effektiv entfernen und den Automatisierungsgrad der Lebensmittelverarbeitung verbessern; Die Lufttrocknung erfolgt bei normaler Temperatur, wodurch die Farbe und Qualität der Materialoberfläche wirksam geschützt wird.

Parameter der Verarbeitungslinie für 400 kg/h Popcorn-Hähnchen

| Nummer | Maschinenname | Parameter |

| 1 | Hühnchen-Popcorn-Schneidemaschine | Modell: TZ-450 Größe: 1700 * 900 * 1450 mm Leistung: 2,2 kW Riemenbreite: 450 mm Maschinenmaterial:304 |

| 2 | Bandförderer | Modell: TZ-500 Größe: 1500 * 600 * 1000 mm Leistung: 0,55 kW Bandbreite: 500 mm Maschinenmaterial:304 |

| 3 | Hähnchen-Popcorn-Schlagmaschine | Modell: TZ-400 Größe: 3020 * 880 * 1250 mm Leistung: 1,3 kW Bandbreite: 400 mm Maschinenmaterial:304 Kapazität: 400 kg/h |

| 4 | Paniermaschine | Modell: TZS-400 Größe: 4660 * 1500 * 2400 mm Leistung: 2,45 kW Bandbreite: 400 mm Maschinenmaterial:304 Kapazität: 400 kg/h |

| 5 | Popcorn-Bratmaschine für Hühnchen und Fisch | Modell: TZ-800 Größe: 4500 * 1100 * 1200 mm Leistung: 124 kW (elektrisch) Bandbreite: 800 mm Maschinenmaterial:304 Kapazität: 500 kg/h |

| 6 | Kühlmaschine | Modell: TZS-800 Größe: 6000 * 1100 * 1100 mm Leistung: 8 kW Bandbreite: 800 mm Maschinenmaterial:304 |

Highlights der Chicken-Popcorn-Produktionsanlage

- Alle Maschinen zur Herstellung von Hühnchen-Popcorn bestehen aus Edelstahl und anderen lebensmittelspezifischen Materialien. Es zeichnet sich durch die Einhaltung von Sicherheits- und Hygienestandards sowie eine einfache Reinigung und Wartung aus.

- Die Produktionslinie für Hühnchen-Popcorn ist vielseitig und für eine Vielzahl von Rohstoffen einsetzbar. Und die hergestellten Produkte zeichnen sich durch guten Geschmack und kräftige Fleischtextur aus.

- Alle Maschinen zur Herstellung von Fischpopcorn sind einfach zu bedienen und hoch automatisiert und werden häufig in Lebensmittelverarbeitungsbetrieben eingesetzt.

- Die Maschine dieser automatisierten Produktionslinie eignet sich nicht nur für die Herstellung von Chicken-Popcorn. Es wird auch häufig für die Herstellung von Hühnersteaks, Fischsteaks, Lotuswurzeln und anderen frittierten Lebensmitteln verwendet.

- Die Frittiermaschine, die Kühlmaschine und das Förderband in der Chicken-Popcorn-Produktionsanlage können je nach Kundenwunsch individuell angepasst werden. Und alle Maschinen zur Herstellung von Hühnchen-Popcorn gibt es in mehreren Modellen. Daher kann die Produktionslinie den Bedürfnissen verschiedener Kunden gerecht werden.