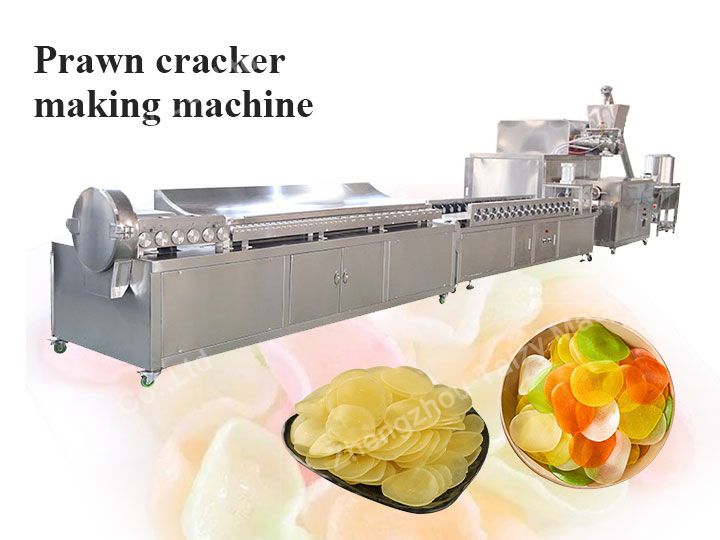

Garnelencracker sind ein beliebter Puffsnack, der hauptsächlich aus Garnelenpulver und Stärke hergestellt wird. Sie sind günstig, lecker, knusprig und reich an Nährstoffen. Besonders bei Kindern sind bunte Garnelencracker beliebt. Wissen Sie, wie man Shrimps-/Garnelencracker industriell herstellt? Eine professionelle Maschine zur Herstellung von Garnelencrackern besteht darin, das Garnelenpulver mit Stärke zu mischen, zu extrudieren, zu dämpfen, Garnelenstangen zu formen, die Stangen zu schneiden, in Scheiben zu schneiden und zu Garnelenchips zu trocknen. Gewöhnlich verkaufte getrocknete, ungekochte Garnelencracker sind bereit zum Braten und dehnen sich sofort aus, werden größer und werden zu köstlichen Garnelencrackern. Die Garnelencrackermaschine ist für Mechatronik konzipiert, mit stabiler Leistung, Mehrzweckmaschine, keiner Rauch- und Staubemission im Produktionsprozess, Umweltschutz, Sicherheit und Hygiene. Somit löst die Garnelen-Cracker-Maschine das Problem der zeitaufwändigen und mühsamen manuellen Produktion. Die Maschine zur Herstellung von Garnelenchips wird häufig in Snack-Food-Verarbeitungsbetrieben, Restaurants, Fast-Food-Läden usw. eingesetzt.

Anwendungen für Garnelencracker

Die Garnelencracker sind in China, Korea, Japan, den Philippinen, Indonesien, Indien, Nepal, Vietnam usw. sehr beliebt. Garnelenchips sind häufig in Fast-Food-Läden, Restaurants, Werkstätten für Gewürzverarbeitung, Snack-Food-Fabriken usw. zu sehen.

Zutaten und Fertigprodukte für Garnelenchips

Allgemeine Rohstoffe: Maisstärke, Tapiokastärke, Garnelenmehl/Garnelenfleisch, Pfefferpulver und andere Gewürze oder Zugabe von Pigmenten usw.

Gängige Fertigprodukte: trockene, ungekochte Garnelencracker, ungekochte Garnelencracker, farbige oder farblose Garnelencracker, Garnelencracker-Chips

Arbeitsvideo einer automatischen Garnelen-Cracker-Maschine

Merkmale und Vorteile der Maschine zur Herstellung von Garnelencrackern

1. Entwickelt mit Mechatronik und stabiler Leistung. Der Garnelencracker-Extruder verfügt über ein integriertes Design, bestehend aus einem Dampfkasten, einer elektrischen Heizvorrichtung, einer Schneckenschnecke, einer Formdüse und einem Motor.

2. Die Garnelenstäbchen haben einen hohen Reifegrad, eine glatte Formung und keine Rauch- und Staubemissionen während des Produktionsprozesses, was umweltfreundlich und schadstofffrei ist.

3. Die Garnelenknackermaschine kann in Verbindung mit der CNC-Schneidemaschine verwendet werden, um die automatische Längensteuerung zu realisieren. Die Länge der Garnelenstange beträgt 50 cm bis 150 cm.

4. Scheibenstärke einstellbar. Die allgemeine Dicke beträgt 0,6 mm bis 3,5 mm.

5. Die materialberührenden Teile bestehen aus lebensmittelechten Materialien, die den Anforderungen der Lebensmittelhygiene entsprechen.

6. Hohe Produktionseffizienz, die Leistung erreicht im Allgemeinen 100–300 kg/h oder mehr.

Wie werden Garnelenchips mit einer Garnelenchips-Maschine hergestellt?

Der Garnelenstäbchen-Extruder verwendet eine neue Technologie der elektrischen Heizung, der elektronischen automatischen Temperaturregelung, des Kochens, Kochens und Formens. Mischen Sie zunächst Garnelenpulver, Stärke, Wasser usw. in einem bestimmten Verhältnis gleichmäßig und geben Sie sie in den Trichter des Garnelenschneiders. Dann drückt das vom Motor angetriebene Schneckenrührgerät die in die Maschine eintretende Aufschlämmung nach vorne und kocht die Aufschlämmung durch das heiße Wasser im Dampfgarer. Anschließend werden die Rohstoffe durch die Form zu feinen, glatten und elastischen zylindrischen oder ovalen Garnelenstäbchen geformt. Lassen Sie die Garnelenstäbchen anschließend abkühlen, bevor Sie sie mit einer Schneidemaschine in dünne Scheiben schneiden. Zum Schluss trocknen Sie die Garnelenchips mit einem Trockner, um das fertige Produkt zu erhalten. Für den direkten Verzehr muss es lediglich in einer Batch-Friteuse frittiert werden.

Maschinenübersicht zur Herstellung von Garnelenchips

Die in der Produktionslinie für Garnelencracker enthaltenen Maschinen sind die Mischmaschine, der Extruder, die Formmaschine, der Garnelenstangenschneider, der Garnelencrackerschneider, die Kühlmaschine und der Trockner. Im Folgenden finden Sie eine allgemeine Einführung in die Funktionen der Hauptausrüstung in der Produktionslinie für Garnelenchips.

Garnelenpulver-Mischmaschine:

Es vermischt Stärke, Salz, frisches Garnelenfleisch, Garnelenöl, Wasser und andere Zutaten gleichmäßig.

Garnelenchips-Extrusionsmaschine:

Das Rohmaterial wird in die Zufuhrvorrichtung gegossen, gepresst und von der Extrudermaschine gekocht, und der Klinker wird durch die Düse extrudiert, um einen zylindrischen Barren zu bilden

Garnelensticks Form-/Gestaltungsmaschine:

Die Maschine zur Herstellung von Garnelencrackern extrudiert die Rohlinge in die Formmaschine. Das Material läuft erneut durch die Form, um Garnelenstäbchen mit einem Durchmesser von 2 bis 5 cm herzustellen

Garnelenstick-Schneider:

Die Länge des Schneidstocks kann je nach Bedarf angepasst werden und die Länge des Schneidstocks beträgt 50 cm bis 150 cm.

Garnelencracker-Schneidemaschine:

Die Scheibendicke des Slicers ist zwischen 0,6 mm und 3,5 mm einstellbar.

Garnelencracker-Trocknungsmaschine:

Dadurch wird der Effekt einer kontinuierlichen Trocknung von Garnelenchips erzielt.

Zugehörige Ausrüstung: Batch-Friteusenmaschine

Um sie direkt zu essen, muss man einfach eine effiziente Batch-Frittiermaschine verwenden, um sie zu frittieren. Die Garnelenchips verdreifachen nach dem Frittieren ihre Größe und schmecken knusprig und köstlich.

Spezifikationen der Garnelenknackermaschine

| Maschinenname | Modell: TZ-6FSJ 100 | Modell: TZ-6FSJ 400 |

| Mischmaschine | Leistung: 3,0 kW Kapazität: 30 kg/Zeit/10 Min Größe: L1050*B910*H1150mm Gewicht: 110 kg | Leistung: 7,5 kW Kapazität: 70 kg/Zeit/10 Min Größe: L1350*B1200*H1450mm N.W.: 200kg |

| Extrudermaschine | Leistung: 20,7 kW Zylinderdurchmesser: 100 mm Kapazität: 100–150 kg Spannung: 380 V, 3 Phasen, 50 Hz Größe: L1850*B810*H1950mm Gewicht: 730 kg | Leistung: 34 kW Zylinderdurchmesser: 126 mm Kapazität: 200–300 kg Spannung: 380/440 V, 3 Phasen, 50/60 Hz, Größe: L2200 x B1700 x H2100 mm N.W.: 1200kg |

| Reextrudier- und Formmaschine | Leistung: 5,5 kW Formgröße: anpassbar Größe: L850*B540*H790mm N.W.: 250kg | Leistung: 7,5 kW Formgröße: anpassbar Größe: L1350*B800*H950mm NW: 450 kg |

| Garnelenstäbchenschneider | Leistung: 1,3 kW Schnittgeschwindigkeit: Einstellbar Größe: L1550*B540*H790mm N.W.: 150kg | Leistung: 3 kW Schnittgeschwindigkeit: Einstellbar Größe: L3550*B740*H1150mm Gewicht: 320 kg |

| Schneidemaschine | Leistung: 5 kW Scheibendicke: 0,6 mm–3,5 mm. Größe: L3650 x B1110 x H1050 mm Gewicht: 410 kg | Leistung: 5 kW Scheibendicke: 0,6 mm–3,5 mm Größe: L3650*B1110*H1050mm Gewicht: 410 kg |

| Trocknungsmaschine | Größe: 8530 x 1320 x 2470 mm Leistung: 75 kW Getriebemotor: 3 kW Anzahl der Schichten: 5 Effektive Förderlänge: 7 m Effektive Trocknungsfläche: 52,5㎡ Effektive Förderbandbreite: 1500 mm | Größe: 11530 x 1320 x 2570 mm Leistung: 95 kW Getriebemotor: 3 kW Anzahl der Schichten: 5 Effektive Förderlänge: 10 m Effektive Trocknungsfläche: 75㎡ Effektive Förderbandbreite: 1500 mm |

Die obige Tabelle zeigt die technischen Daten der Hauptkomponenten von zwei Standardmodellen: Modell TZ-6FSJ 100 und TZ-6FSJ 400. Neben den Hauptmaschinen sind auch unterstützende Geräte wie Hebezeuge, ein Kühlgerät und eine Sortiervorrichtung enthalten Maschine. Bei Bedarf können wir auch weitere Zusatzgeräte zur Verfügung stellen. Das Modell TZ-6FSJ 100 ist bei kleinen Garnelen-Cracker-Herstellern beliebt und das Modell TZ-6FSJ 400 mit größerer Leistung eignet sich für mittlere Garnelen-Chips-Unternehmen. Bei den Spezifikationen handelt es sich um Standardtypen, und nicht standardmäßige Spezifikationen können ebenfalls angepasst werden.

Als führender Hersteller von Maschinen für die Lebensmittelverarbeitung bieten wir hochwertige Maschinen und zuverlässigen Service aus einer Hand. Unsere Garnelenknackmaschine ist in vielen Ländern wie Indien, Japan, den Philippinen usw. einer unserer Bestseller. Für detaillierte Informationen und den besten Preis können Sie uns gerne kontaktieren.