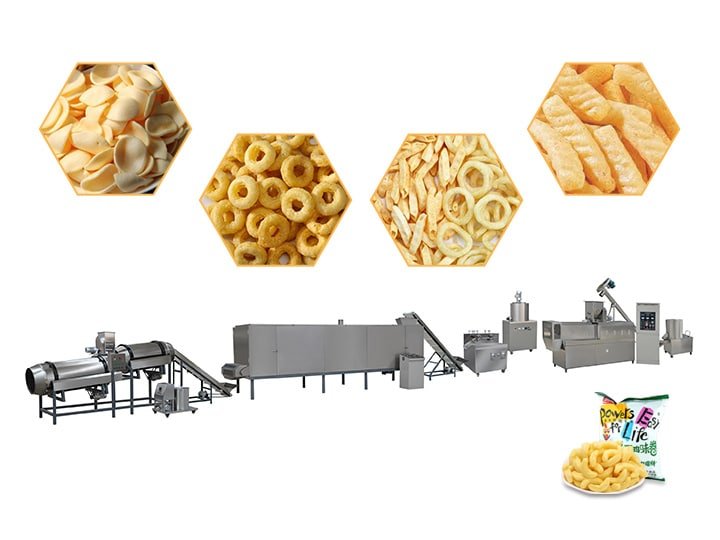

The puffed snack production line takes a series of production steps to produce various puffed cereal snacks. The corn puff production line consists of ingredients selection, mixing, extrusion, forming, baking (frying), seasoning, and other steps. The snack food processing line can complete the above steps at one time, with high production efficiency.

How to make puffed food?

Puffed snacks are made from grains such as rice, millet, and soybeans through high-temperature extrusion, baking, and seasoning.

The puffed grains are convenient to store, and transport, and rich in nutrients. Moreover, the puffing technology for making puffed food has the characteristics of wide application, simple process, and high production output. Therefore, the extruded snacks line is also widely welcomed.

Classification of the puffed snack production line

According to the maturation methods difference, the puffed snack production line can be divided into a baking-type snack pellet production line and a fried-type snack food processing plant.

The deep-fried type uses fat as the heating medium to mature the grains. The baking type mainly ripens raw materials with hot air as the medium. At present, baking type is the most common way on the market.

The two ways mainly to dehydrate the extruded food are through frying or baking. This can reduce puffed food moisture to make sure better quality. And it also can play a role in sterilization. The following takes the baking type as an example to introduce the puffed snack production steps.

Corn puffed snack production line flow chart

How does the snack making machine make corn puff? The extruded snacks manufacturing process includes raw material selection, extrusion, molding, baking, seasoning, and packaging.

Mixer

The mixer is used to mix powdery raw materials and liquid seasonings evenly. The humidity and starch content of the raw materials will directly affect the degree of puffing. Therefore, when selecting raw materials, it is better to choose moderate water content and starch content raw materials.

Snacks puffing machine

The corn puff making machine is the most important machine in puffed food manufacturing. In the corn puff cereal machine, the raw materials are steamed and shaped at high temperatures. Then it will squeeze into shapes through the holes of the mold. Therefore, you can make different puffed foods by changing different shapes and molds.

Different puffing molds are available

Molding machine (optional)

This machine is suitable for making long strips of pasta-puffed food. The long noodles made by the puffing machine are pulled into the forming machine. Then, the puff maker machine’s blade cut the long strips into small regular shapes. Customers can choose this snack making machine according to their production process.

Baking machine

The molded puffed snack has not yet really matured, it needs a roasting machine for high-temperature baking and curing. The snacks baking machine can maintain snacks’ nutrients and taste.

Seasoning machine

In order to obtain a unique taste, it is necessary to use a seasoning machine for seasoning. The seasoning machine has the characteristics of continuous operation and will not damage the structure of the puffed food.

Packaging machine

To facilitate storage and transportation, it is necessary to pack puffed food. We provide packaging machines that can produce bag and box packaging styles.

Factors affecting the quality of puffed corn

The ideal puffed food should be a product that is highly fluffy, uniform in structure, consistent in appearance, crispy taste, and has good flavor. However, in actual production, there are many factors that affect the quality of puffed food.

The dough composition

The protein, fat content, and moisture content in the dough affect the structure of the dough. These will ultimately affect the shape of the puffed food during puffing.

The heating speed

The heating speed and temperature should be appropriate. Too fast heating speed will vaporize water molecules quickly, causing grains to expand too quickly. As a result, the surface of the puffed food instantly loses water and hardens.

Industrial puffed snack production line advantages

- The puffed snack food production line can realize a one-time completion from raw material mixing to finished product packaging. It has the characteristics of high production efficiency and high degree of automation.

- This snack food processing line has a wide range of applications. It can produce various shapes of products by changing molds and production processes.

- The use of the baking machine has changed the unhealthy problem of fats and oils caused by the previous frying technology. And it not only simplifies the production process but also helps maintain the flavor and nutrients of the product.

- These puffed snack production machines are easy to operate, with low investment cost and high production efficiency.

- We provide different specifications for snack pellet production plant lines, it meets the needs of different customers.

FAQ about the puffed snack production line

What kind of puffed food can be produced by the corn puff processing line?

This line has a very wide application, it can puff most extruded foods seen on the market. For example, cheese balls, corn chips, puffed rice, puffed chips,…

How to replace the extruded machine mold?

We have the instruction manual to guide you.

What is your puffed snack production line production time?

According to the situation of the production line you buy, it usually takes about 10-20 days.

What about your after-sale service?

We have a professional after-sales team to solve your problems. No matter what kind of technical problems you encounter, please contact us in time, and we will solve your problems for you as soon as possible.