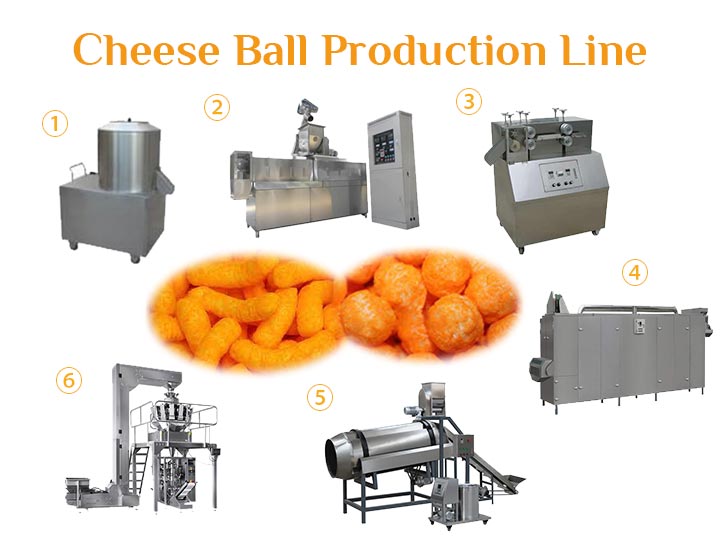

As a cheese ball making machine manufacturer, we have produced automatic cheese ball production lines for many years. Cheese ball production equipment mainly contains a dough-making machine, puffing machine, pulling and cutting machine, frying machine (or baking machine), seasoning machine, and packaging machine. The cheese ball making machine is also applicable to the production of various puffed snack food, such as corn chips, corn flakes, and cereal puffed products.

Cheese ball production process

Our company offers professional cheese ball making machines. The production steps of cheese balls include dough mixing, extruding, cutting, frying/baking, seasoning, and packaging. In a fully automatic cheese ball production line, all the major machines mentioned above are needed and it is also necessary to use a hoister and conveyors as supporting equipment.

Dough-maker machine

The dough mixer machine is widely used in bakeries, cake shops, restaurants, households, and other places. It is the first part of the cheese ball machinery. In the mixer, powdery ingredients and water can mix uniformly. The spiral stirring hook rotates in the mixer, and the maize hominy is constantly pushed, pulled, kneaded, and pressed, thus quickly mixed.

In this way, the dry maize hominy can obtain uniform hydration and become a dough with elasticity and uniform flow. Notably, the degree of puffing is affected by the humidity and starch content of the raw materials. Therefore, while selecting raw materials, it is preferable to pick raw materials with the proper content of water and starch.

Technical data

| Machine name | Dough-maker machine |

| Model | TZ-III |

| Voltage | 380V/50HZ |

| Installed power | 3KW |

| Motor power | 3KW |

| Output | 10-15kg/batch (5min) |

| Dimension | 0.8×0.6×1.2m |

Double-screw extruder

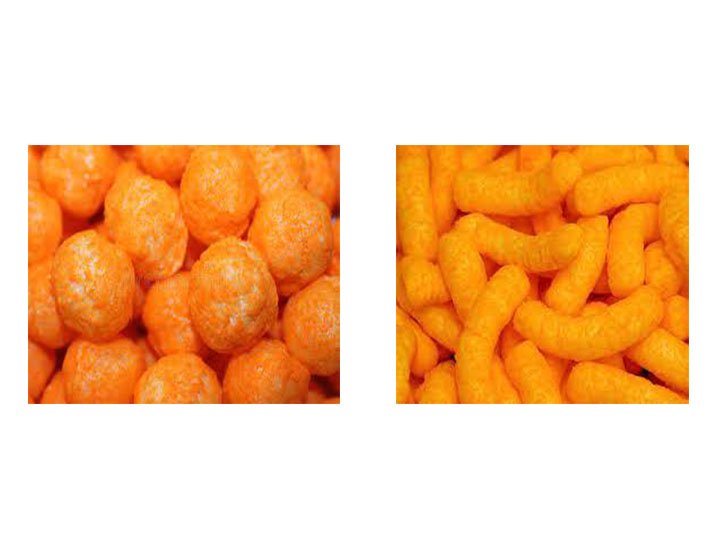

The twin-screw extruder is an essential one among cheese ball making machines. The corn puff making machine produces puffed food by processing various grains, such as rice, millet, corn, soybean, and wheat. Its main working principle is to extrude food with the heat generated when the machine rotates.

An obvious feature of puffed food is that its size becomes larger. The puffed food has a crisp taste, and unique flavor, easy to digest and carry. It is an ideal leisure food for consumers. The raw materials can be shaped in the holes of special molds at high temperatures. Changing the types of molds can result in puffed foods of different shapes.

Puffing machine working video

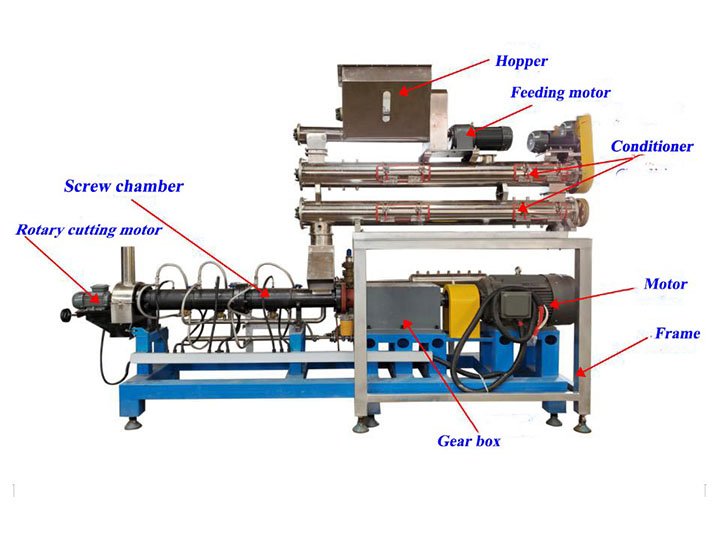

Structure of maize puffing machine

The cheese ball making machine comprises a feeder, cylinder, gearbox, motor, frame, rotary cutting system, control system, and others. The extruder has a set of screws and screw sleeves, called an expansion cavity.

After entering the expansion chamber, the raw materials are squeezed, rubbed, and sheared between the screw and the screw sleeve. Then, the internal pressure and temperature rise continuously, so the material starch gelatinizes. After coming out from the outlet, the pressure and the temperature suddenly decrease, and the water flashes, so the material shows a porous or flocculent appearance.

Advantages of maize puffing machine

- Various models and outputs. Such as 100-150kg/h, 200-300kg/h, etc.

- High-quality product. Uniform size and attractive appearance

- Extrude molds can be customized based on the customer’s needs.

- Diverse heating ways: steam and electric heating methods

Parameter of cheese ball making machine

| Machine name | Double-screw extruder |

| Model | TZ65-II |

| Voltage | 380V/50HZ |

| Installed power | 35KW |

| Motor power | 22KW |

| Output | 100-150Kg/h |

| Screw length | 1050mm |

| Screw diameter | 65mm |

| Dimension | 2.6×1.0×1.8m |

Cheese ball cutter machine

The pulling and cutting machine is the supporting equipment for the dough maker or corn puffing machine. The lengthy materials are dragged to the cheese puffs cutter machine. The lengthy strips are then chopped into little uniform triangle shapes by the blades of the food shaping machine. Customers may select specific shaping equipment with other molds or blades based on their needs.

Cheese ball fryer & baking machine

Fried or baked cheese balls are both popular with many people. We have cheese balls fryers and cheese ball baking machines to produce fried or baked cheese puffs.

Continuous deep fryer

The continuous deep frying machine can realize continuous frying with controllable temperature. With advanced heating technology and structure, the mesh belt fryer is oil-saving and energy-saving. This fried food shows a bright color and a crispy taste.

Technical data

| Machine name | Continuous deep frying machine |

| Model | TZ-III |

| Voltage | 380V/50HZ |

| Installed power | 55KW |

| Motor power | 40KW |

| Output | 100-150Kg/h |

| Dimension | 4.5×1.2×1.95m |

Baking machine

To produce batches of baked cheese balls, it is needy to use an industrial cheese balls baker. The roaster machine for cheese balls can maintain the original nutrients and taste.

Flavoring machine for cheese balls

It is important to utilize a flavoring machine to achieve a distinct flavor. The seasoning machine is designed for even mixing and flavoring without damaging the shapes of puffed food.

Parameters of flavoring machine

| Machine name | Flavoring machine |

| Model | TZ-II |

| Voltage | 380V/50HZ |

| Installed power | 0.75KW |

| Output | 100-300kg/h |

| Rotary drum length | 2100mm |

| Dimension | 2.1×0.6×1.8m |

Cheese balls packaging machine

Puffed food needs to be packed for storage and delivery, and we offer various types of packaging equipment for puffed food. The packaging weight and packing size can be customized based on customers’ needs.

Supporting equipment of cheese ball making machine line

Feeding conveyor

Voltage: 380V, 50Hz, three-phase

Power: 1.1Kw

Speed: 140rpm/min

Size: 3000*600*3000mm

Function: convey mixed flour into the extruder. There is a wheel on the screw conveyor, which is easy to move.

Cooling conveyor

Rated power: 0.55kw

Constant speed operation

Fan power: 0.18kw 2

Dimensions: 5000*600*1100mm

Material: 304 stainless steel mesh belt

Rack: 201 stainless steel

Actually, we provide many types of machines with different outputs and efficiency. Also, customized services are available. If you have any specific requirements for our cheese ball making machine, feel free to get in touch with us. Our Taizy factory can formulate cost-effective puffed food processing solutions for you according to your processing needs and investment budget.