A corn puff extruder also called a screw extruder machine, is designed to produce puffed foods. The raw materials are mainly corn, rice, millet, beans, and other grains. Different molds can be used to make finished products of various shapes. Puffed food is crisp and tender, suitable for all ages. The maize puffs machine is favored by a large number of customers because of its compact structure, safe and simple operation, and considerable economic benefits. Do you know the structure of the double screw extruder and how the corn puff extruder works?

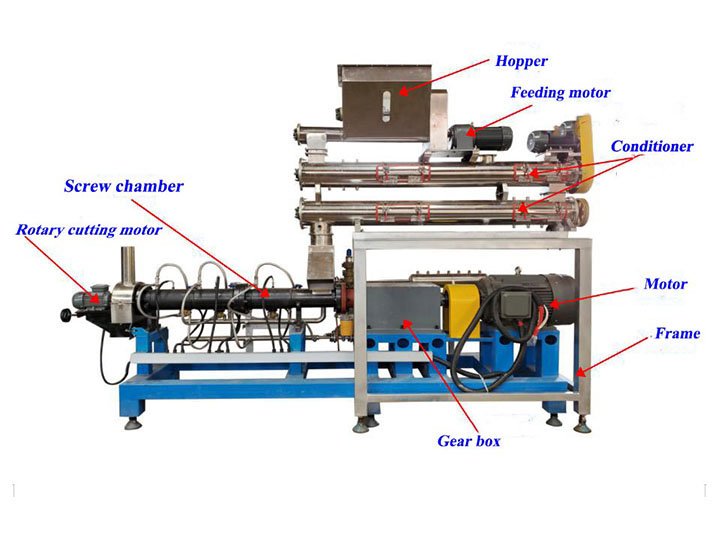

Maize puffs machine structure

A corn puff extruder generally contains the parts of feeding, extrusion, heating, rotary cutting, and so on. The extruder cavity adopts a multi-section building block type. Each cavity can independently control the temperature. There are heating and cooling channels inside, and it adopts electric or steams heating. The temperature is automatically controlled. It is more convenient and accurate to control the temperature of extruded products, so as to ensure the taste and quality of products. Because the machine adopts screw forced feeding, the feeding is uniform, so as to avoid uneven input of raw materials and the different extruding effects of products.

How the corn puff extruder works?

The main working principle is that mechanical energy is transformed into thermal energy. The thermal energy generated by rotating and extrusion of the maize puffs machine greatly expands the shape of raw material.

Compared with a single screw extruder machine, a double-screw extruder has a better forced feeding effect. Two screws meshing with each other rotate in the same direction and finish the conveying task, friction extrusion, and heating. The screws convey materials according to the principle of positive displacement.

The powdery raw materials are extruded from powder to paste, and the raw fiber is partially degraded and refined. This process can not only effectively kill microorganisms and bacteria, but also make paste materials eject from the gap of the mold under the action of strong pressure difference. During this time, the materials instantly form extruded products with a loose structure and good appearance.

If you have any inquiries about our corn puff extruder machine, welcome to contact us.