Almonds are also very popular as ingredients in casual snacks, baked goods, and other fields. Therefore, the need for almond peeler is increasing. The data shows that the utilization rate of almonds has achieved rapid growth in the food field, with a 95% growth in the nutritious food market, 13% growth in the dairy market, and 10% growth in the dessert and ice cream markets.

The growth of the almond market has also brought challenges and opportunities to almond peeler

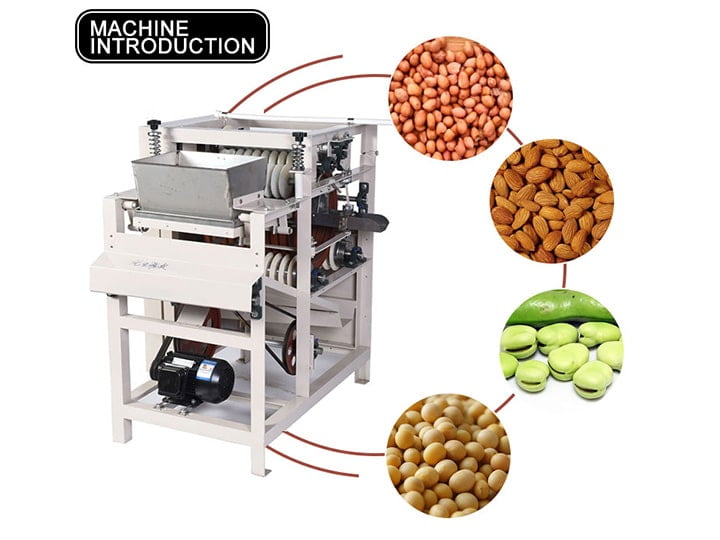

As we all know, the almonds are not only wrapped around the shell but also are wrapped by a thin skin. When processing almond milk, almond oil, almond flour, and other foods, to ensure the taste, the almonds must be peeled. It is necessary to use an almond peeling machine.

Types of almond peeling machine

Almond peeling machines currently on the market include wet type peeling machines and dry type peeling machines. Before using a wet peeling machine, you need to blanch almonds with a high temperature in hot water. The peeling rate in this way is good with high efficiency.

Nowadays, with the development of technology, a dry type peeling machine is applied in the field of almond peeling. Unlike the former, the almonds need to be roasted before peeling to make them contain less than 5% water. Almonds are peeled by differential rolling friction. Dry almond peeling machine has two functions such as peeling and separating. The almonds are peeled evenly, and it is also convenient for subsequent deep processing.

How to improve the market competitiveness of the almond peeling machine?

With the expansion of the almonds market, the penetration of almond peeler will further increase. So, from what aspects should relevant equipment manufacturers start to improve the market competitiveness?

First of all, it is necessary to further improve the peeling effect of almond peeler. The supplier should constantly innovate and optimize the spare parts so that the crushing rate is lower and the peeling rate is higher.

Secondly, manufacturers should strengthen the stability of equipment operation. Under the specified working environment, the operation of the almond peeling machine should be stable for a long time, including the quality of the finished product and the accuracy of the equipment parts.

Besides, improving the automation of the almond peeling machine is also critical. You can try to add a PLC automatic control system to reduce labor intensity and time.