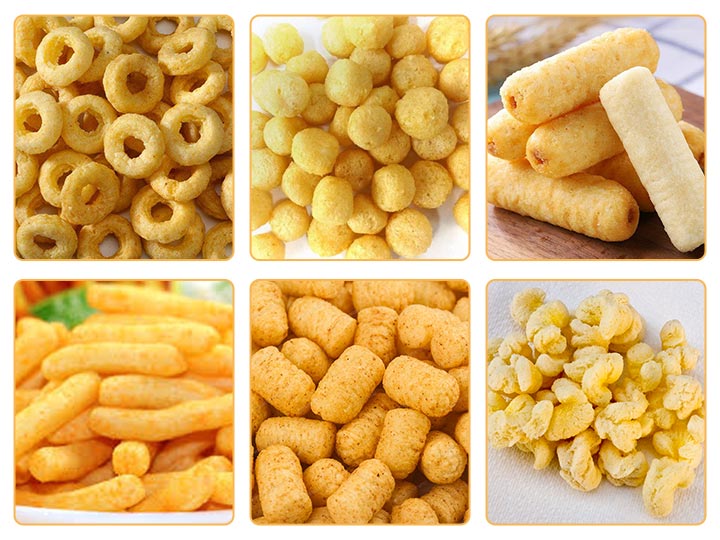

Puffsnacks zeichnen sich durch einen knackigen Geschmack, eine leichte Verdauung sowie einen veränderlichen Geschmack und eine veränderliche Form aus. Es erfreut sich bei jungen und alten Menschen auf der ganzen Welt großer Beliebtheit. Unter ihnen ist Mais-Puff der beliebteste Puff-Snack. Als Hersteller von Maschinen zur Herstellung von Snacks stellen wir Ihnen im Folgenden vor, wie Sie Maisbrei mithilfe der Maschinen herstellen.

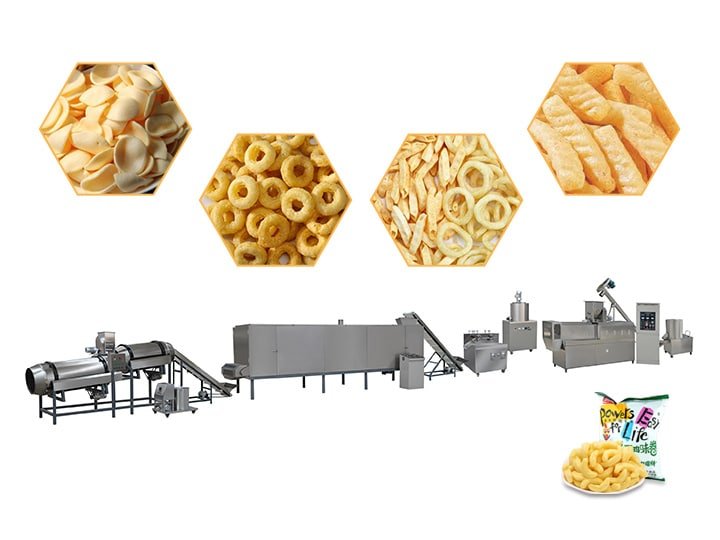

Die Zusammensetzung der Snack-Produktionslinie

Bei der Massenproduktion von gepufften Lebensmitteln ist es unvermeidlich, Snackmaschinen zur Herstellung von gepufften Lebensmitteln zu verwenden. Welche Art von Maschine sollten wir angesichts der verschiedenen Maschinen zur Herstellung von Puffsnacks auf dem Markt wählen, um Puffsnacks zuzubereiten?

Bei den meisten Puffsnacks sind die Produktionsschritte ungefähr gleich. Seine Produktionsschritte sind im Allgemeinen das Mischen von Pulver, das Puffen, Backen (Braten), Würzen, Verpacken usw. In der kommerziellen Produktion gibt es für jeden Schritt eine entsprechende Maschine zur Herstellung von Maisbrei.

Hersteller von Snackmaschinen führt Produktionsschritte für Maisblätterteig ein

- Die Mischmaschine eignet sich zum Mischen von Speisestärke und anderen Gewürzen. Sie können den Geschmack verändern, indem Sie andere Gewürzpulver hinzufügen.

- Die Maisbeutelmaschine extrudiert zunächst das Maismehl bei hoher Temperatur. Nach druckreduziertem Puffen, Abkühlen, Trocknen und anderen Prozessen im Puffwirt bildet es dann eine bestimmte Form. Insbesondere befindet sich am Ende der Puffmaschine eine Extrusionsdüse. Durch diese Form kann eine bestimmte Form des Maiskolbens expandiert werden. Der Hersteller von Taizy-Snackmaschinen bietet verschiedenen Kunden eine Vielzahl von Formen zur Auswahl.

- Obwohl die Rohstoffe bei hohen Temperaturen in der Extrudermaschine extrudiert werden, ist der Puffmais noch unreif. Daher ist eine Maschine zum Backen oder Frittieren für die Sekundärhärtung erforderlich. Die Backtechnologie durchbricht den ungesunden Mangel, der durch übermäßiges Fett entsteht. Gleichzeitig kann die Verwendung einer Bäckereimaschine zum Backen den Proteinverlust im Maismehl reduzieren.

- Um sicherzustellen, dass das gepuffte Essen seinen vollen Geschmack erhält, ist eine Würzmaschine für verschiedene Geschmacksrichtungen erforderlich. Wir bieten eine kontinuierliche Würzmaschine und eine Achteck-Würzmaschine an. Sie eignen sich für große, mittlere und kleine Puffpflanzen.

- Im letzten Schritt wird eine Verpackungsmaschine benötigt, um Mais-Puffs zu verpacken, damit sie bequemer gelagert und transportiert werden können. Je nach Verpackungsstil bieten wir unterschiedliche Verpackungsmaschinen an.

Die oben genannten Schritte sind die Schritte zur Herstellung von Puffmais. Um den Bedürfnissen der Kunden mit unterschiedlichen Spezifikationen gerecht zu werden, bietet der Hersteller von Snackmaschinen Produktionslinien mit unterschiedlichen Spezifikationen und Leistungen an. Darüber hinaus ist die Pufffutterlinie auch für unterschiedliche Rohstoffe geeignet.