Chin chin cutting machine is a multifunctional pastry-cutting machine, which is developed by simulating the principle of manual cutting food. The cutter can make different foods by adjusting different cutters. And the chin chin cutter machine can adjust the thickness and size of the finished product.

The pasta food cutting machine has a wide range of applications and a high degree of automation. It is widely used in pastry shops, pasta processing plants, pastry processing plants, etc. The cutting machine also can equip with a dough pressing machine, frying machine, packaging machine, and other machines to form a chin chin production line.

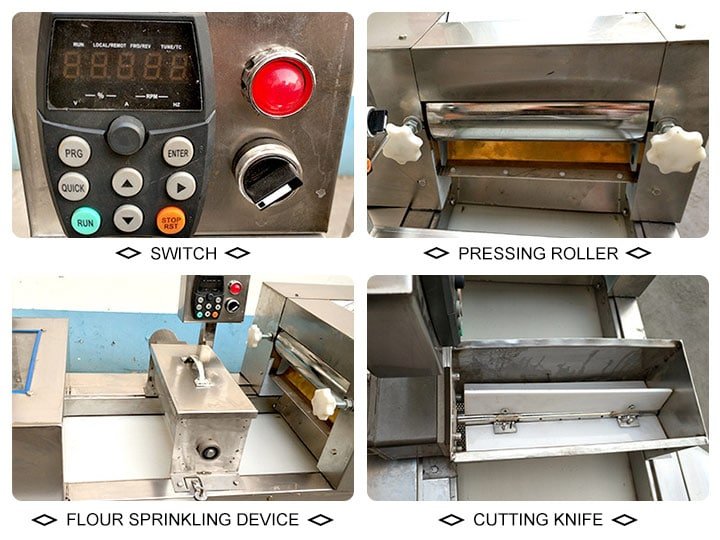

Chin chin cutting machine structure

The commercial chin chin cutting machine is mainly composed of a frame, a transmission part, a pressing part, a conveying part, and a pastry forming mechanism, including a frequency conversion speed regulation mechanism.

Industrial chin chin cutting machine working principle

Put a certain amount of dough on the dough feeding board and turn on the chin chin cutting machine. The dough will be conveyed to the rollers at a constant speed. It will automatically complete the process of feeding and pressing under the action of the conveyor belt and pressure roller and reaches the set processing thickness.

The gap between the pressing roller and conveyor can adjust by adjusting the adjusting wheel, so the user can adjust the thickness of the final product according to the actual situation.

After pressing, the dough passes through an automatic flouring device. Then it will be conveyed to the cutting knife, and then cut into shape by the cutting knife. The chin chin cutter can be customized to cut into slices, blocks, silk, dice, diamonds, curves, and other shapes.

Parameters of chin chin cutter machine

Model: TZ-350

Capacity: 300kg/h

Power: 2.2kw

Voltage: 220v, 50hz

Size: 2600*720*1180mm

Weight: 300kg

Advantages of electric chin chin cutting machine

1. Wide application range and high output;

2. Save labor, only need 1-2 people, reduce work labor intensity;

3. The chin chin cutting machine adopts a protective cover at the cutter to ensure safe use;

4. All stages run synchronously, and the dough will maintain a complete shape;

5. The cutters are evenly distributed, making the cutting more thorough and the size more standard.

Precautions for using the multifunctional pasta cutting machine

1. When using, the pasta cutting machine should be placed on a level work site to make the machine run smoothly;

2. Before use, check all parts of the machine and secure the loose screw;

3. Check whether there is any foreign matter in the barrel. If there is any, please clean it up before turning on the power, so as not to transmit to the cutter and damage the cutter;

4. When the chin chin cutter machine is running, it is strictly forbidden to reach into the barrel;

5. Before cleaning and disassembling, you should disconnect the power to stop the machine;

6. You should change the lubricating oil at the bearing regularly.