The automatic chicken nugget production line contains a series of fried nugget processing machines for producing chicken nuggets. According to the production steps of fried chicken nuggets, the chicken nugget processing line mainly includes forming machine, battering machine, flour coating machine, crumb coating machine, frying machine, and other machines. The automatic fish nugget production machine has the characteristics of large production output, easy operation, and cleaning. And this chicken nuggets production line is not only suitable for making chicken nuggets, but it is also suitable for making fish nuggets, hamburger patties, pumpkin pie, potato cakes, and other fried products.

Application of fried chicken nuggets production line

Many food processing plants may need to process multiple products. In order to save budget, they need to use general-purpose machines to process these products.

The chicken nugget processing equipment in the automatic fried chicken nugget production line can be widely used in the fried food production line. Especially for the chicken nugget forming machine, it can change the shape and size of the forming mold to make different fried foods. Therefore, using this automated chicken nugget production line can produce chicken nuggets, onion rings, fish nuggets, squid rings, vegetable cakes and many other fried foods.

Chicken nuggets pretreatment equipment

For different customers, his production materials and finished products may be different. Some customers will use pure chicken to produce fried chicken nuggets. Some customers may use other ingredients to make fried chicken nuggets. Before the formal production, the chicken meat needs to be processed.

The equipment for pretreatment of fried chicken nuggets generally includes meat grinders, mixers, freezers, and other equipment.

The meat grinder is used to stir the whole meat into thin strips, which is convenient for subsequent processing.

The blender can be used to mix chicken and other seasonings.

The freezer is mainly used to freeze the processed chicken raw materials, which is convenient for storage and maintains the freshness of the meat.

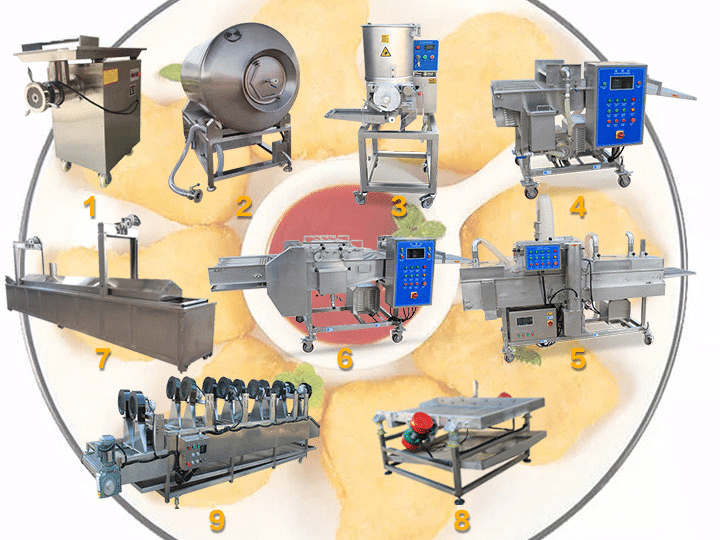

The chicken nuggets production line flow chart

The chicken nuggets produced by this automatic chicken nugget production line have mainly undergone the steps of forming, battering, flouring, battering, breading, and frying.

Chicken nugget forming machine

The chicken nugget forming machine can automatically complete the filling, forming, sticker, output, and other processes of the filling. By changing different molds, the forming machine can make hamburger patty, fish nugget,potato patty, and other parties. The forming machine has several models, it can customize single-row, double-row, or even three-row molds according to the formed chicken nugget diameter.

Battering machine

This step is to apply a thin layer of slurry on the surface of the chicken nuggets to achieve the purpose of pre-battering. It mainly coats the surface of chicken nuggets with a layer of slurry through two slurry curtains and a slurry pool at the bottom. The machine equips with a powerful fan to blow off the excess slurry to achieve a uniform coating.

Preduster machine

Place the flour in the hopper of the machine in advance, and it will evenly distribute a layer of flour on the mesh belt. When the chicken nuggets pass through the conveyor belt, they can be evenly coated with a layer of flour. The machine’s mesh belt speed can be adjusted and it is also suitable for bread crumbs with a diameter of less than 3mm.

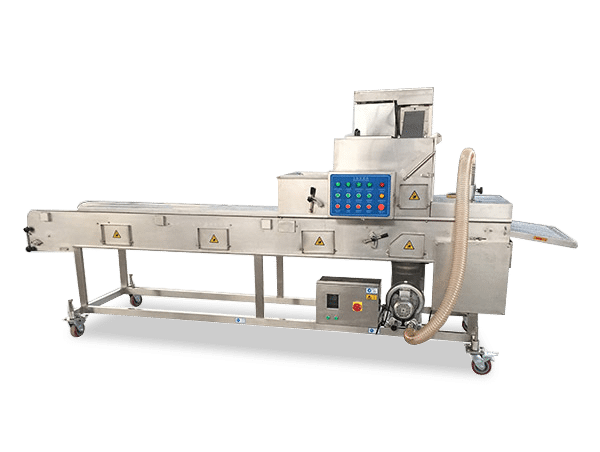

Tempura battering machine

The thick battering machine is an immersion battering machine, and the thick slurry is distributed in a recessed tank. When the chicken nuggets enter the tank containing the thick slurry through the conveyor belt, the chicken nuggets are coated with a layer of thick slurry.

Chicken nugget frying machine

It is very important for frying chicken nuggets in the nugget production line. For the continuous frying machine, The heating temperature and heating time can be adjustable according to different raw materials. Moreover, it can maintain a constant oil temperature to make sure fried products maintain good color and flavor during the frying process.

Commercial fried chicken & fish nuggets production line working video

The chicken nugget processing line advantages

- All the machines in the nuggets production line are in contact with food, all 304 stainless steel.

- The product transmission is continuous during the production process, clean and tidy.

- It can customize a variety of molds for producing different products, so the nuggets production line has a wide application.

Chicken Nugget production line frequently asked questions

How much is the machine cost?

Different models have different price, just tell us your requirement, our sale will suggest you suitable model and price.

What is the raw material of your machine?

Our machines are made of stainless steel material, if you have special requirement for the machine, just feel free to tell us

What if the voltage can’t fit our country?

The voltage can be customized, just tell us before the machine is made.

Could you send your engineers to come here to install the machine?

For all machines in the chicken nuggets production line, the machine is installed already.When you receive the machine,you can use it directly.

How is the occupitation of these machines?

Each machine has different models, and the different customer has different requirements for the production line. We can equip the machine according to the customer’s site, or we can design a placement plan for you.