The chin chin production line is used to make fried chin chin, which is popular in Nigeria, Ghana, and other places. The industrial chin chin processing line mainly applies to the whole process from flour to dicing to frying and packaging.

The chin chin frying production line mainly includes a dough mixer, dough pressing machine, chin chin cutting machine, automatic discharging fryer, bottom discharging deoiling machine, and packaging machine. The production line has large production output and complete molding, which is an ideal machine for processing frying chin chin.

The production line has a capacity of 200–300 kg/h, making it ideal for small to medium-sized enterprises. All machines in the line are made of full 304 stainless steel, ensuring safety, durability, and easy cleaning.

What is chin chin?

Chin chin is a popular fried snack from West Africa, especially Nigeria and Ghana. It is made from flour, sugar, and butter or oil, shaped into small pieces or sticks, and deep-fried until crispy. Chin Chin is crunchy, slightly sweet, and enjoyed as a snack or treat at parties and gatherings.

The machines involved in the chin chin production line

| Number | Machine name |

| 1 | dough mixer |

| 2 | dough pressing machine |

| 3 | chin chin cutting machine |

| 4 | automatic deep fryer |

| 5 | deoiling machine |

| 6 | chin chin packaging machine |

Frying chin chin production process

1.dough mixer

The dough mixer is used to mix flour, sugar, butter, milk and other materials. The dough mixer is made of all stainless steel, and the output is large, and the working noise is extremely low. There is a food machine auger inside to mix the materials evenly.

2.dough pressing machine

The full-automatic dough pressing machine adopts high-quality pressing rollers, and the non-stick dough conveyor belt presses the dough repeatedly, which makes the gluten strong and tough.

3.chin chin cutting machine

The chin chin cutting machine cuts the pressed dough into small pieces. The cutting machine can adjust the thickness of the formed dough by adjusting the gap between the pressure roller and the conveyor belt. And it also can adjust the size of the final product by adjusting the distance of the blades. In addition, the automatic chin chin cutting machine can customize different cutting shapes blades to make different products.

4.chin chin deep frying machine

The circular fryer is an automatic undischarging fryer. Moreover, it also can install an automatic feeding device to realize automatic frying work. And the chin chin frying machine also contains an automatic stirring gear, which can automatically stir the materials during frying to make the materials evenly fried. According to the different heating sources of customers in different regions, our machines have electric heating and gas heating heating methods.

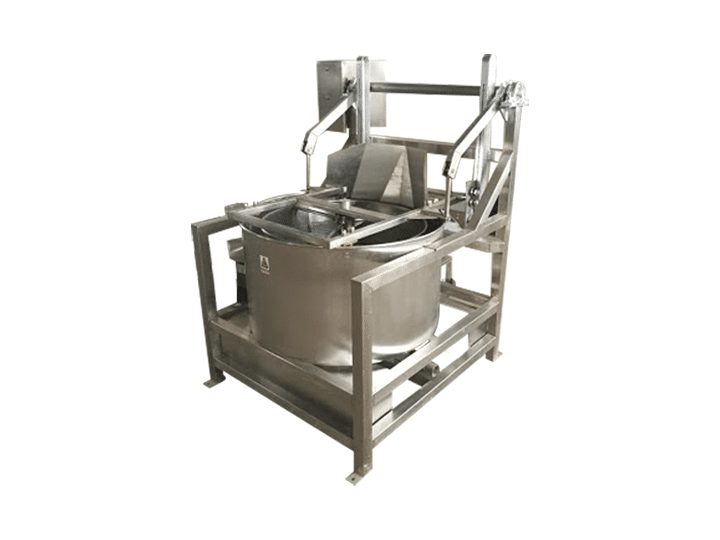

5.deoiling machine

After frying, a de-oiling machine with bottom discharge is needed. The deoiler adopts centrifugal method to remove excess oil on the surface of the material. And the machine can automatically discharge materials. Generally speaking, the machine need a conveyor belt to holdup the raw material and cooling.

6.chin chin packaging machine

The chin chin packaging machine is a relatively high automatic machine. It can complete a series of tasks such as automatic weighing, automatic blanking, automatic sealing, and labeling. And the packaging machine suits a wide range of raw materials, it can pack tea, grain, powdery materials, liquid materials and other raw materials. And we can customize the machine according to customer’s requirements.

Advantages of chin chin production line

- All the machines are made of 304 stainless steel, which can be used for a long time;

- The cost of investing in the production line is low, the manufacturers for this processing line can get a return quickly and profit from it;

- The chin chin processing line can make a variety of pasta by changing different molds;

- The production line has a variety of output options to meet the needs of different customers.

Chin chin production line – 200–300 kg/h technical parameters

| Item | Model | Specification |

|---|---|---|

| Dough mixer | TZ-50 | Capacity: 50 kg/batch Mixing Time: 3–10 min Voltage: 380 V, 50 Hz Power: 3 kW Weight: 200 kg Size: 1300×600×700 mm |

| Flatter machine | TZ-500 | Capacity: 200 kg/h Voltage: 220/380 V, 50 Hz Power: 3 kW Weight: 245 kg Size: 1060×610×1330 mm Max Width: <500 mm Thickness: 6–14 mm |

| Cutting machine | TZ-120 | Capacity: 150–300 kg/h Voltage: 220/380 V, 50 Hz Power: 2.6 kW Size: 1200×750×1200 mm Weight: 180 kg Note: Includes 1 cutter, extra cutter optional |

| Frying machine | TZ-150 | Total Power: 72 kW Mixer Power: 1.5 kW Output Power: 1.5 kW Size: 1750×1700×1700 mm Work Space: 1500×350 mm |

| De-oil machine | – | Size: 1470×1100×1580 m Power: 2.2 kW Bucket Size: Ø750×H410 mm Outer Barrel: Ø910×H510 mm Weight: 430 kg |

| Packing machine | TZ-320 | Power: 1.8 kW Raw Material Weight Range: 8–500 g Membrane Width: max 320 mm Capacity: 100–130 pcs/min Size: 750×1150×1950 mmWeight: 250 kg |

Notes:

- The frying machine can be equipped with either electric heating or gas heating.

- All the above equipment is configured as one complete set.

What shapes of chin chin can this processing line produce?

The production line can produce chin chin in various shapes, including sticks, strips, cubes, and small bite-sized pieces, depending on the cutter or mold used. Different shapes of chin chin can be produced simply by changing the molds during operation.

FAQ

What is the output of this production line?

Because each machine has multiple models, we will match the production line to you according to customer needs;

Can you change the machine voltage?

Yes, we will change the local voltage for customers in different countries;

After receiving the machine, how to operate, is there an instruction manual?

Yes, we will provide detailed instructions for use, and when necessary, we will provide video guidance;

How about your after-sales guarantee?

We will pay regular visits to customers for the use of the machine.Any problems, we will help customers solve the problems as soon as possible.

Export cases

Chin chin making machine in Nigeria